Plastics are an excellent material choice for many applications throughout diverse industries, including medical, defense, aerospace, automotive, and consumer products. Polyhistor has extensive experience working with the world’s most exotic plastics, and we’d love for you to put our plastic machining services to the test!

Blog

Capability Highlight: Polyhistor’s Reverse Engineering Services

Most product development services begin with a sketch, a 2D drawing, or a 3D model. But thanks to a process known as reverse engineering, you can also use an existing product to inform and inspire your next project. Polyhistor’s reverse engineering experts can dissect and deconstruct your physical product, extracting valuable insights and data which […]

Did You Know…? 5 Polyhistor Services That May Surprise You

We’re proud of our reputation for exceptional product development and engineering design. But did you know we also offer a tremendous range of in-house capabilities, from CNC machining to 3D printing to complete contract manufacturing services? Polyhistor can fulfill your project goals throughout every phase, from the design room to the production floor. Did You […]

Why Manufacturing Partners Are Key During Product Development

Your design is complete, and orders are already coming in for your new product! Now is not the time to discover manufacturability issues that will make your product challenging—or even impossible—to produce. Unfortunately, roadblocks are extremely common when bringing a design to life. But there’s good news! With a slight shift in your product design […]

5 Reasons to Choose Polyhistor for High-Volume Production Machining

Let Polyhistor advance your parts seamlessly from product development to production! We leverage our team’s engineering expertise to ensure cost-efficient Design for Manufacturing (DFM), top-quality machining services, and short lead times with on-time delivery. High-Volume Production Machining at Polyhistor As a product development and engineering design firm specializing in rapid prototyping, 3D printing, and CNC […]

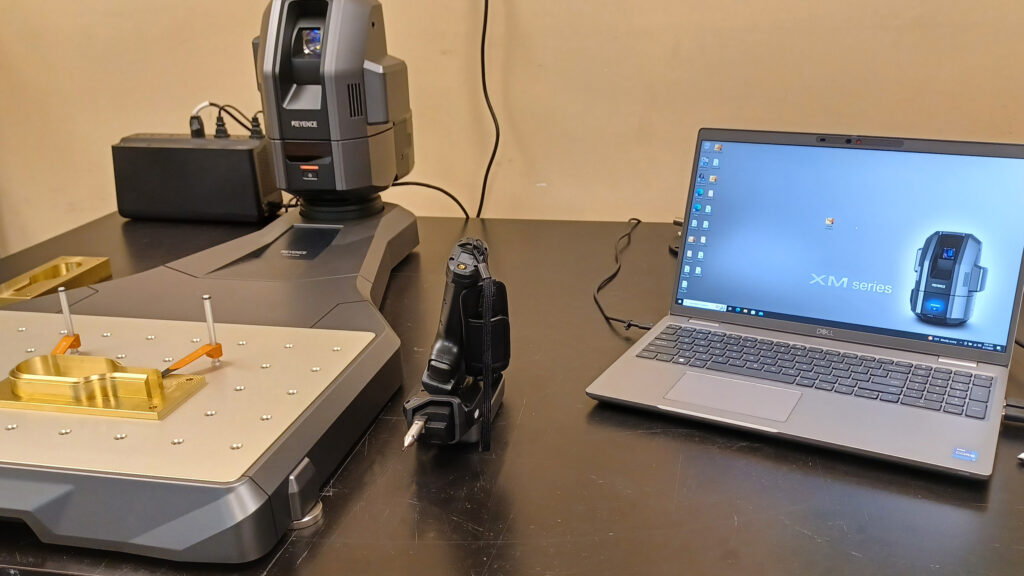

How Our New CMM Improves Part Accuracy and Quality

Your low-volume, high-mix precision parts deserve exceptional accuracy. Now, with our precision machine shop’s newly installed Keyence coordinate measuring machine (CMM), we can achieve better accuracy than ever before. Complex parts with tight tolerances are Polyhistor’s specialty, and the Keyence CMM takes our inspection processes to the next level, ensuring the ultimate accuracy for every […]

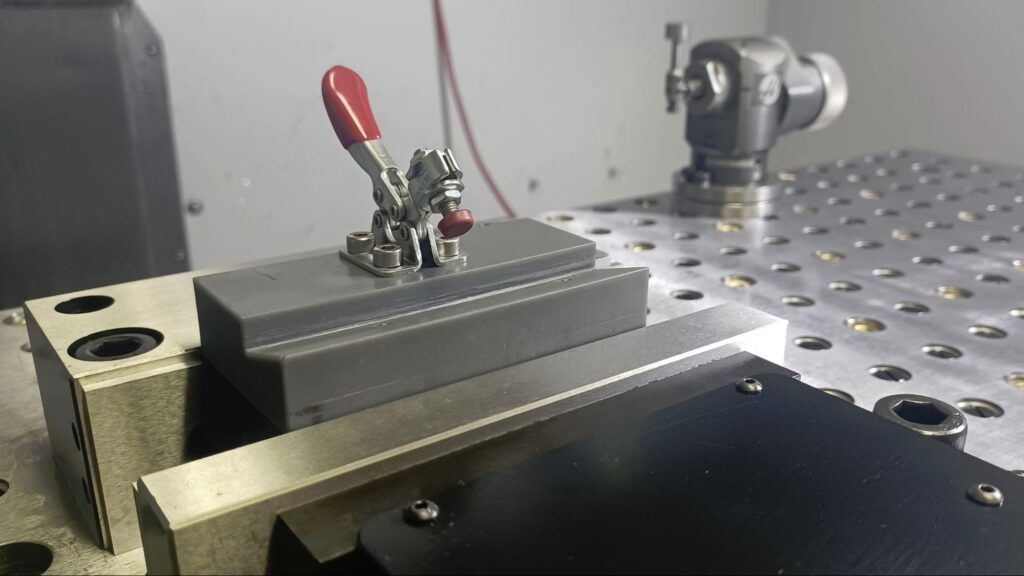

3D Printed Custom Fixtures: A Low-Cost Solution for Prototypes and Low-Volume Parts

Fixtures are essential to every CNC machine shop’s manufacturing processes. But when parts require custom fixtures, those fixtures can be expensive to make in-house and even more expensive to purchase from an outside supplier. So how does Polyhistor manage the hundreds of custom fixtures we need each year for our customers’ prototypes and low-volume parts? […]

Important Considerations for Plastic Machining Services

Let’s assess how to go about selecting a plastic for your part and examine the factors engineers should consider during the design process. Selecting a Plastic for Your Part Not all plastics are created equal, so you should familiarize yourself with the characteristics of common plastics before determining which material is best suited for your […]

Enhance Your CNC Machined Parts with In-House Laser Engraving Services

Would you like your CNC machined parts engraved or etched with serial numbers, part markings, or even your company logo? Add laser engraving services to your next CNC machining order! Polyhistor’s Jacksonville, Florida facility provides in-house CO2 laser engraving and fiber laser engraving, giving you access to affordable laser engraving services for everything from individual […]

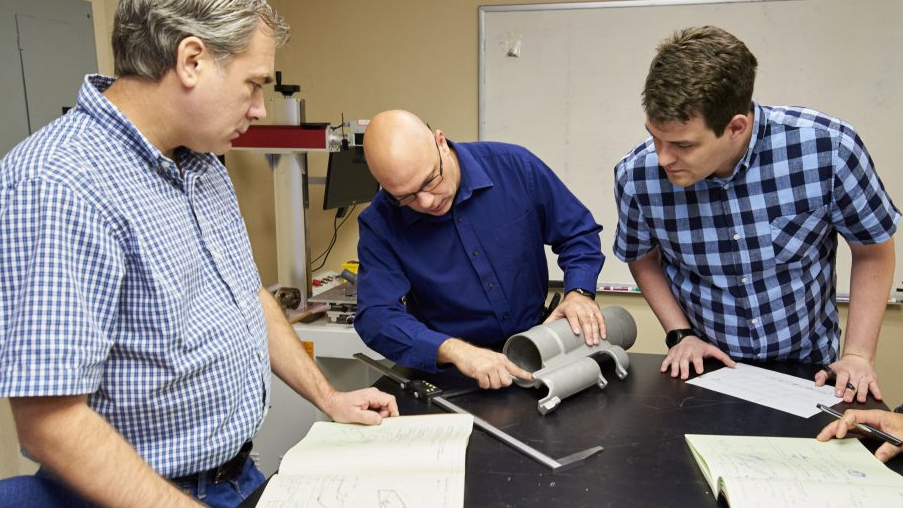

Polyhistor’s Customer-Centric Approach to Manufacturing

What sets Polyhistor apart from most job shops? Our custom manufacturing experts are also engineers. This distinction means you benefit from highly skilled professionals who approach every prototype, part, and product through an engineering lens. We’re adept at identifying design issues, brainstorming solutions, and recommending modifications. Made by Manufacturers, Optimized by Engineers Here’s how Polyhistor’s […]