Fixtures are essential to every CNC machine shop’s manufacturing processes. But when parts require custom fixtures, those fixtures can be expensive to make in-house and even more expensive to purchase from an outside supplier.

So how does Polyhistor manage the hundreds of custom fixtures we need each year for our customers’ prototypes and low-volume parts? We 3D print them.

3D Printed Fixtures Secure Your Parts and Prototypes for Less

While there are many types of standard fixtures, custom fixtures are often necessary due to a part’s material or geometry.

As one of the premier prototype companies in Florida, Polyhistor uses custom fixtures every single day to secure workpieces for machining. For high-volume orders, it makes sense to invest in longer-lasting, CNC machined custom fixtures; for lower-volume jobs, however, 3D printing is faster, more affordable, and 100% up to the task.

Real Customer Story: Getting the Job Done Right

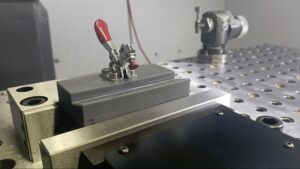

Jobs like the one we’re about to describe look simple on paper. Our customer needed two holes drilled into each of their 100 parts, but the parts were challenging to hold in place on our machine. We knew we needed a custom fixture to secure the parts, but the cost of precision machining a fixture didn’t make sense for the size and scope of the job.

So we relied on our tried-and-true 3D printing experts to print a low-cost custom fixture that would allow us to complete the job correctly, on time, and within our customer’s budget.

The Advantages of 3D Printed Custom Fixtures

Our CNC machine shop is certainly equipped to make fixtures the traditional way, but the drawbacks to machined fixtures extend beyond high costs. Machining a custom fixture absorbs valuable programming and machining time that could otherwise be dedicated to making parts for our customers—like you!

On the other hand, 3D printing offers several distinct advantages:

- No programming. To 3D print a custom fixture, our team only needs to design and print it—no programming required. And because the printer can run unattended, it doesn’t pull any of our skilled experts away from the floor.

- No delays. Because 3D printing doesn’t utilize a CNC machine, we can maintain our production flow even as we print custom fixtures. Our CNC machine shop stays on schedule, and every customer’s parts get delivered on time.

- No restrictions. Sometimes, to most effectively secure a part, the fixture needs to be somewhat complex. A machined complex fixture would likely be entirely too costly—particularly for prototypes or low-volume parts. However, a 3D printed complex fixture can easily be tailored to a part’s exact needs without excess cost or time requirements.

3D Printed Fixtures: Another Way Polyhistor Turns Big Ideas into Real-World Products

The path from napkin sketch to finished product is rife with unexpected challenges. 3D printing custom fixtures is only one example of the practical solutions Polyhistor brings to the journey. Relevant to every job, however, is our team’s commitment to quality and clear communication.

Whether you’re looking for CNC machining in Jacksonville, specifically, or simply want a product development and engineering design firm you can trust, the Polyhistor team is here to bring your designs to life. From high-profile prototypes to low-volume part runs, Polyhistor approaches every project with care, creativity, and cost-consciousness.