At Polyhistor International, we’re always looking for every possible way to make your project more efficient and cost-effective. It’s part of our collaborative mindset—we view all of our customers as true partners. We’re committed to enabling their success in any way we can, whether through custom order options or design for manufacturing guidance. One behind-the-scenes […]

Blog

4 Best Practices for Developing Electromechanical Assemblies

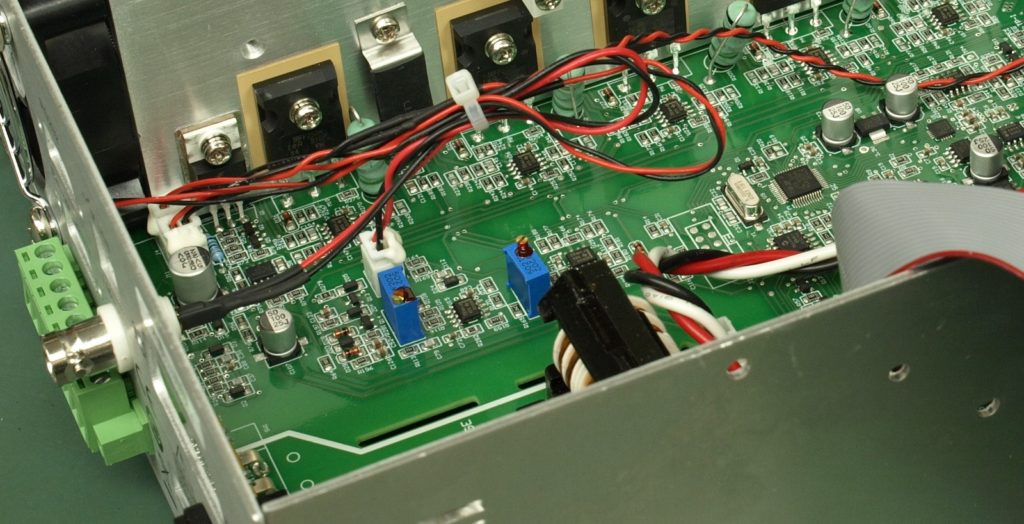

Does your next project require electrical engineering, prototyping for electrical components, or electromechanical assembly? With Polyhistor’s advanced product engineering services, your ideas come alive as tangible, superior-quality products. While nothing in the manufacturing world is truly simple, electromechanical parts and products introduce a unique layer of complexity to precision machining. Electromechanical prototypes, for example, tend […]

5 Reasons Polyhistor Is a Great Place to Work

With people as incredible as ours, a small precision machine shop can deliver BIG solutions. Polyhistor International is responsible for transforming customers’ innovative ideas into successful products—a task that isn’t possible without brilliant product development, engineering, and manufacturing experts like you on our team. Interested in joining us? Take a look at what makes Polyhistor […]

Design for Manufacturing Tips for Precision Machining: 4 Features to Avoid

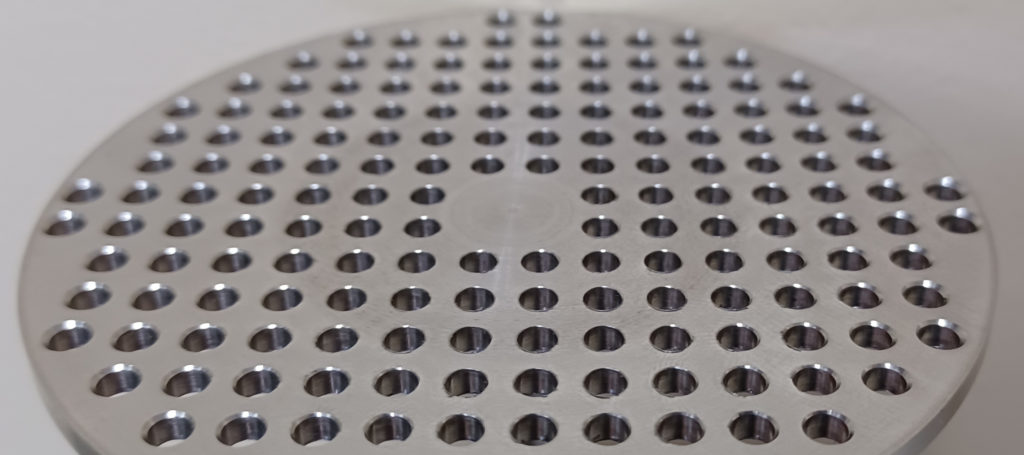

When developing a part or product for precision machining, it’s important to consider how your design will translate onto the shop floor. Manufacturability issues can increase a project’s cost and lead time, and it’s best to get ahead of any potential roadblocks during the design phase. Our cost-saving Design for Assembly (DFA) tips have helped […]

5 Ways to Optimize Your Timeline for Contract Manufacturing Services

Time is always of the essence in manufacturing. There are so many moving parts involved in bringing a product from concept to completion—and plenty of opportunities for things to go wrong and timelines to get delayed. It certainly doesn’t help that the manufacturing industry is uncharacteristically volatile at the moment. Global supply chain disruptions and […]

How to Successfully Supply Materials for Precision Machining

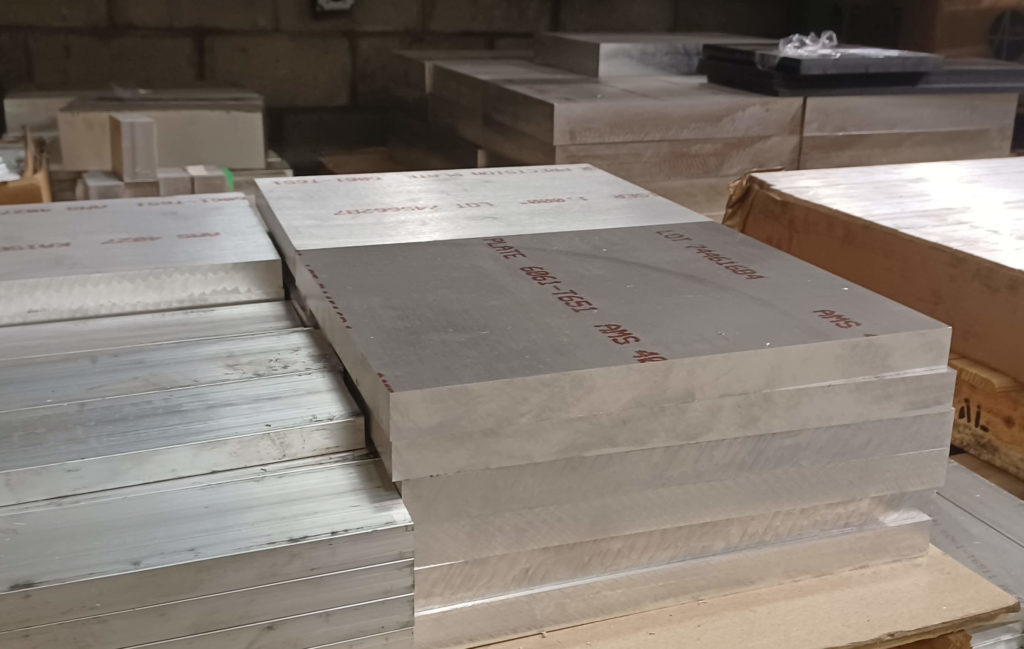

Many manufacturing customers assume that supplying their own materials will save them money on precision machining services. But unless you already have the material in stock or are using a proprietary or custom-made material, it’s best to let your contract manufacturing partner manage material orders. This option minimizes back and forth and is often more […]

The Value of Submitting a 2D Drawing with Your Quote

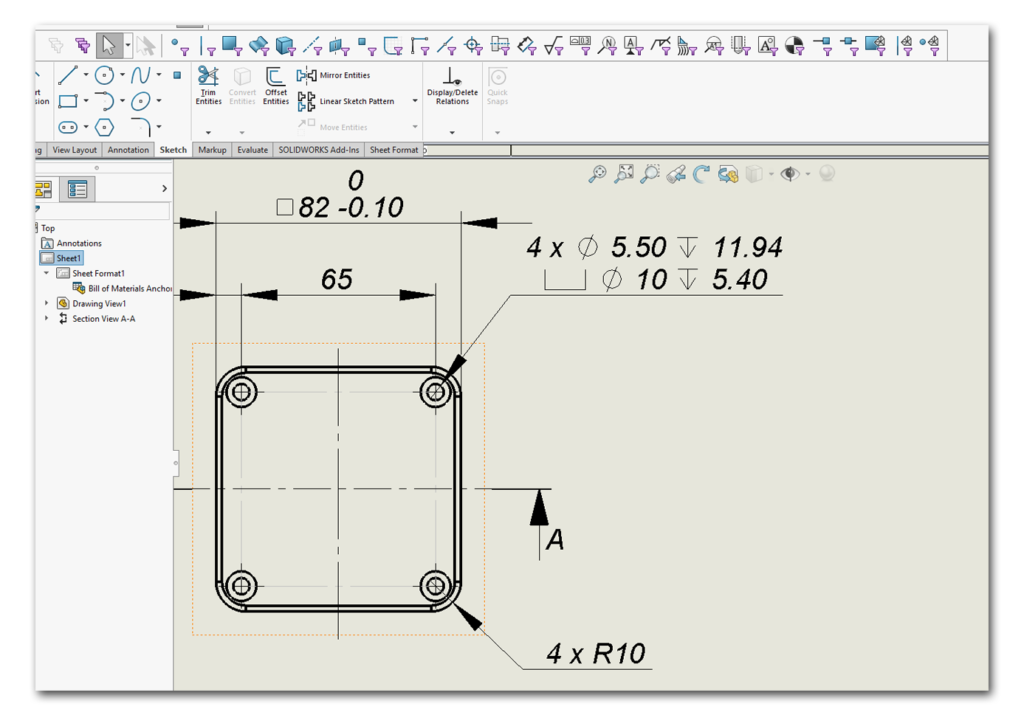

There’s no doubt that STEP files—the standard file format used for 3D CAD models—have been a game-changer for manufacturing. Engineers (including the ones on our team!) often default to STEP files because the generic file format is compatible with most systems. Manufacturers appreciate receiving these files because, unlike other 3D file formats containing multiple configurations […]

When to Bring a Contract Manufacturer into Your Product Development Process

As an engineering-based manufacturing company, we’re honored to help many small to medium sized businesses transform their ideas into tangible products. Our product development services offer customers across all industries a viable path forward for new and exciting innovations. If you’re a product developer thinking about reaching out to us for these services, you may […]

Turnkey Contract Manufacturing: from Concept to Completion

Product designers usually have a clear vision of how they want a product to look and function. But if they don’t have a strong engineering background, they can face difficulties navigating the numerous steps that must take place between product concept and finished product. Partnering with a contract manufacturer early on in the design process […]

5 Considerations for Ceramic Machining Applications

According to the American Ceramic Society, the oldest known ceramic artifact is dated as early as 28,000 BCE. Indeed, humans have been manufacturing and using ceramics since ancient times. Ceramic applications have evolved substantially over the last 30,000 years. These days, the material is used in everything from bricks for building houses, to kitchen knives, […]