As an engineering-based manufacturing company, we’re honored to help many small to medium sized businesses transform their ideas into tangible products. Our product development services offer customers across all industries a viable path forward for new and exciting innovations.

If you’re a product developer thinking about reaching out to us for these services, you may be wondering when to bring us into your process. Whether your priority is cost, lead time—or both—we want you to get the most out of your partnership with Polyhistor.

Let this blog post serve as your guide for getting the timing of your engagement with a contract manufacturer just right.

Partnering with a Contract Manufacturer Too Early

The true success of a product can’t only be measured when it’s in the hands of your customers. Product developers who engage a contract manufacturer too early in the process risk investing in a product that won’t yield a good return on investment.

Before requesting product development services, it’s important to have these foundational elements in place:

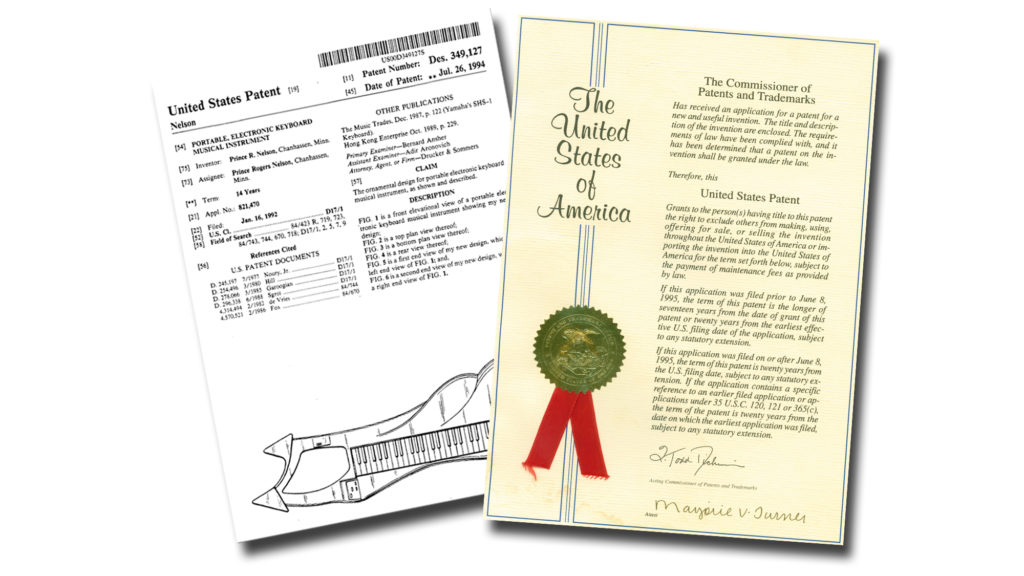

- Background research to minimize the risk of intellectual property infringement

- Market validation that confirms there is consumer demand for your product

- A go-to-market strategy for selling the product (or the patent, if you’re focusing solely on IP)

As you conduct due diligence, you may want to engage a business consultant and an IP attorney to help ensure that your product idea can viably move on to development.

Partnering with a Contract Manufacturer Too Late

On the other hand, it’s also possible to partner with a engineering based, contract manufacturer too late! We’ve seen customers go through the entire process of obtaining a patent for their product, only to discover that it can’t be manufactured as designed.

Amending a patent can be expensive and time-consuming, and we want our customers to avoid this scenario whenever possible.

The Right Time to Partner with a Contract Manufacturer

So, when is the appropriate time to partner with a contract manufacturer for product development services? There are two right answers to this question:

- After you’ve conducted due diligence. Minimal design isn’t a problem for our team, provided you’ve covered your bases when it comes to background research, market validation, and go-to-market strategy. At Polyhistor, we provide concept sketching and product design services as a precursor to prototyping and production. Many customers without in-house product development resources rely on us as their outsourced engineering department.

- When you’re ready for prototyping. Customers with in-house engineering expertise frequently come to us for prototyping with their designs already underway. We consult with them on Design for Manufacturing (DFM) and Design for Assembly (DFA), material selection, and finishing options before moving into prototyping and possibly even production.

When you bring us in right on time, we can also liaise with your IP attorney to ensure that any designs and prototypes aren’t at risk of IP infringement. We can even refer you to trusted attorney resources we have successfully worked with in the past.

Ready to work with Polyhistor on your new product? We can’t wait to see what you’ve come up with. Contact us today to learn more about our product development services!