Businesses that rely on manufacturing to make parts and products have faced immense challenges over the last year, from global supply chain shortages to rising costs of raw materials. While it’s encouraging to see America reopening, many of these challenges aren’t going away anytime soon.

As businesses ramp up production again, there’s an increasing demand to reduce costs as much as possible. Unfortunately, everything seems to be more expensive right now—not only material, but hardware, too (we’ve seen a simple electrical box increase as much as 50%!).

At Polyhistor, we hear our customers’ frustrations loud and clear, which is why we’re doing everything we can to help them cut costs on material, hardware, and labor. Today, we’re sharing our list of tips on how to reduce costs for assemblies.

Design for Assembly Tips: 24 Ways to Reduce Costs for Assemblies

One of the simplest ways to reduce the overall cost of an assembly is to limit the number of individual components involved.

Added costs are mostly attributed to individual parts. If you design your assembly with as few parts as possible, then the price per assembly will inevitably come down. When you’re dealing with production volumes, having a lower cost per part can make a considerable difference in the overall cost of the assembly.

Want more tips for reducing cost on part assemblies? Here’s the list of Design for Assembly (DFA) tips from our machine shop in Jacksonville:

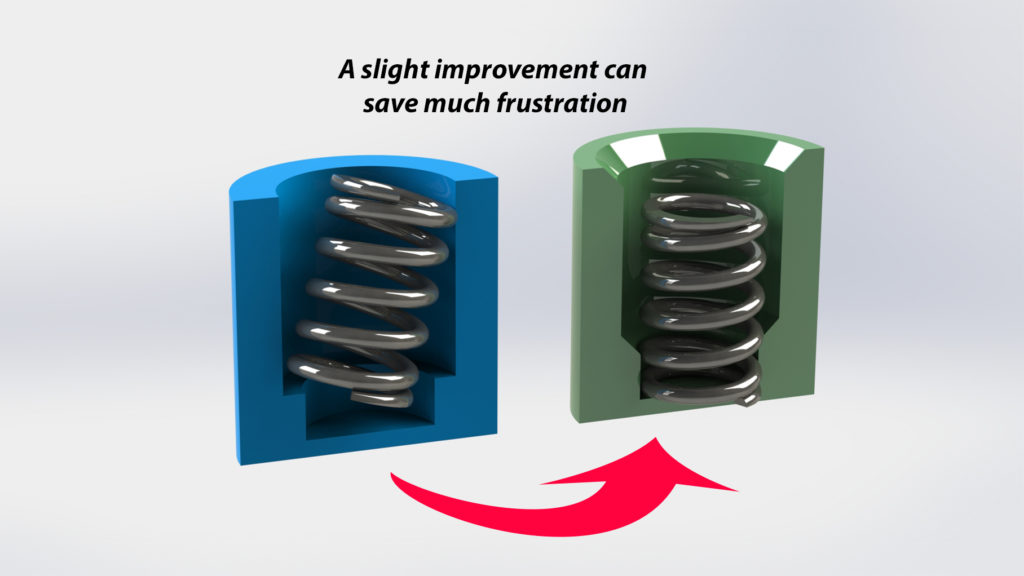

- Minimize part count by combining components together

- Minimize handling during assembly

- Maximize ease of assembly

- Minimize the number of operations

- Utilize self-locating features

- Utilize self-fastening features

- Minimize reorientation needs

- Design parts for ease of handling and insertion

- Top-down assembly

- Maximize use of standard parts

- Reduce the number of fasteners in an assembly

- Utilize modular assemblies (sub-assemblies)

Ready for the next 12? Check out the rest of our cost-saving DFA tips here.

At Polyhistor, we’re always looking for innovative ways to solve manufacturing challenges through creative and innovative thinking. Your success is our success.

If you’re interested in our product design services or you’re just looking for an excellent machine shop in Jacksonville, request a quote and let’s work together.