Aluminum is second only to steel in popularity, and it’s easy to see why! Pure aluminum is plentiful, comprising 8% of the Earth’s crust. In its many alloyed forms, aluminum’s unique properties make it a top choice for a wide range of industries and applications. Let’s explore further. Advantages of Aluminum in Manufacturing At Polyhistor, […]

Blog

5 Tips for Selecting the Best Hardware for Any Product

Hardware is critical to any assembly’s success, so we work closely with you to identify the best hardware for your goals. Polyhistor’s unique blend of product design services, on-site engineering expertise, and high-volume CNC machining capabilities equip us to advise you on the various fasteners available and recommend the right solution. Here, we’ve outlined the […]

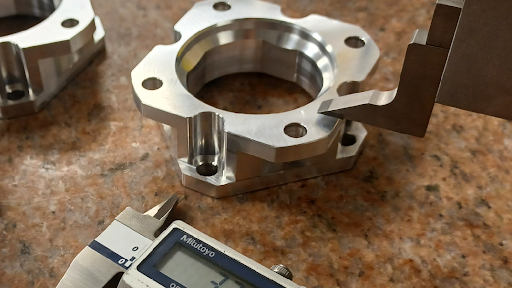

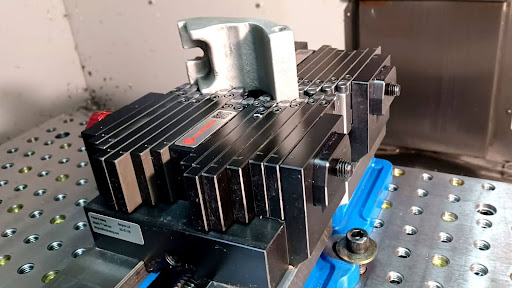

How Modular Vise Systems Promote Manufacturing Efficiency

Even low-volume productions of high-mix parts require workholding, but machining custom jaws for a short production run is almost never efficient or cost-effective. By utilizing modular vise systems in place of custom jaws, our precision machine shop can keep production times short and costs low.

Finishing Considerations for Contract Manufacturing Services

“Finishing” may sound straightforward, but it actually encompasses a wide range of options and considerations that can seriously impact a manufacturing project’s success. As part of our contract manufacturing services, Polyhistor offers a comprehensive range of finishing services in-house and via a network of trusted vendors. Before you make a choice, let’s dive into some […]

Planning for High-Volume Production Machining: What to Know

In the competitive world of product development, every business aims to eventually transition from low to high-volume production. This shift may seem daunting, but with the right planning, a move to high-volume production machining can be both seamless and lucrative for our customers. Polyhistor’s Approach to High-Volume Production High-volume production is defined by its scale, […]

8 Exotic Plastics to Consider for Plastic Machining Services

Plastics are an excellent material choice for many applications throughout diverse industries, including medical, defense, aerospace, automotive, and consumer products. Polyhistor has extensive experience working with the world’s most exotic plastics, and we’d love for you to put our plastic machining services to the test!

Capability Highlight: Polyhistor’s Reverse Engineering Services

Most product development services begin with a sketch, a 2D drawing, or a 3D model. But thanks to a process known as reverse engineering, you can also use an existing product to inform and inspire your next project. Polyhistor’s reverse engineering experts can dissect and deconstruct your physical product, extracting valuable insights and data which […]

Did You Know…? 5 Polyhistor Services That May Surprise You

We’re proud of our reputation for exceptional product development and engineering design. But did you know we also offer a tremendous range of in-house capabilities, from CNC machining to 3D printing to complete contract manufacturing services? Polyhistor can fulfill your project goals throughout every phase, from the design room to the production floor. Did You […]

Why Manufacturing Partners Are Key During Product Development

Your design is complete, and orders are already coming in for your new product! Now is not the time to discover manufacturability issues that will make your product challenging—or even impossible—to produce. Unfortunately, roadblocks are extremely common when bringing a design to life. But there’s good news! With a slight shift in your product design […]

5 Reasons to Choose Polyhistor for High-Volume Production Machining

Let Polyhistor advance your parts seamlessly from product development to production! We leverage our team’s engineering expertise to ensure cost-efficient Design for Manufacturing (DFM), top-quality machining services, and short lead times with on-time delivery. High-Volume Production Machining at Polyhistor As a product development and engineering design firm specializing in rapid prototyping, 3D printing, and CNC […]