There’s no doubt that STEP files—the standard file format used for 3D CAD models—have been a game-changer for manufacturing.

Engineers (including the ones on our team!) often default to STEP files because the generic file format is compatible with most systems. Manufacturers appreciate receiving these files because, unlike other 3D file formats containing multiple configurations for the same part, a STEP file provides just one configuration, minimizing confusion and streamlining quoting.

A STEP file is great for clarifying the physical geometry of a part. And if you have multiple components in an assembly, the file demonstrates precisely how those components fit together.

But despite the indisputable advantages of STEP files, there is one major drawback. In simplifying the presentation of the model, much of the detailed information—including part specifications—is lost.

For this reason, Polyhistor advises customers to include a 2D drawing in addition to a STEP file when requesting contract manufacturing services.

Why Submit a 2D Drawing with Your STEP File?

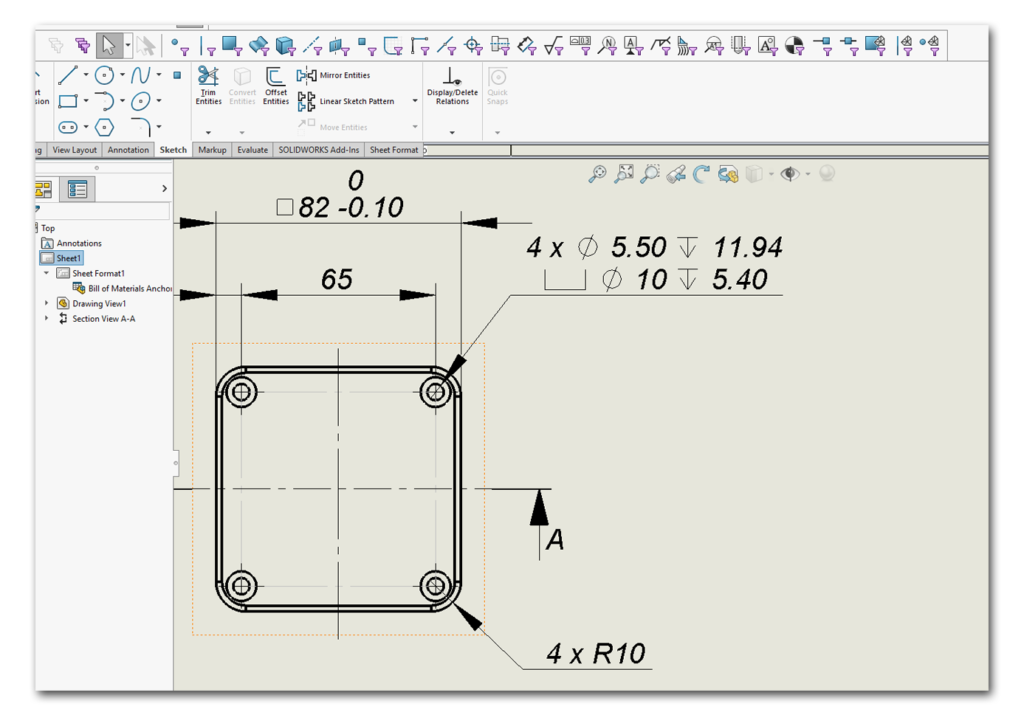

Let’s take a closer look at some of the vital information provided in a 2D drawing:

1. Critical tolerances

Knowing critical tolerances is essential to manufacturing a part that fits and functions as intended. A STEP file includes minimal information about tolerances, whereas a 2D drawing clarifies these specifications in great detail, leaving no room for error or confusion.

2. Surface finish instructions

Surface finish instructions (e.g., powder coating, anodizing) are important for manufacturers to have at the start of a project. In addition to clarifying the type of finishing required, be sure to tell us whether the dimensions you’re including are pre-finish or post-finish. We may need to adjust the dimensions of your part during the machining process to ensure that we meet all final specifications.

3. Hole callouts

Holes are critical features on many parts, and as such, it’s important to include detailed information about them in the 2D drawing.

First, we’ll need to know whether each hole is threaded or not. If a hole is threaded, include your preference for thread cutting or thread forming and the standard thread tolerance. Don’t worry about specifying drill sizes. We’ll make those determinations on our end.

We’ll also need to know general hole tolerances to determine whether to use a reamer, a mill, or a drill to make your holes.

Simply put, including a 2D drawing with sufficient information minimizes back and forth when you request contract manufacturing services. And it allows manufacturers to get to work quickly on your part.

Don’t have a 2D drawing? No problem! The team at Polyhistor has the ability to make one for you. We’ll always do what it takes to get our customers the parts they need.

Ready to get started on your next project? Request for a quote today!