Many manufacturing customers assume that supplying their own materials will save them money on precision machining services.

But unless you already have the material in stock or are using a proprietary or custom-made material, it’s best to let your contract manufacturing partner manage material orders. This option minimizes back and forth and is often more cost-effective in the end. Polyhistor maintains accounts with most material suppliers and can leverage our purchasing power to negotiate optimal prices in many cases.

Ultimately, our goal as a turnkey contract manufacturing services provider is to make our customers’ lives easier. We encourage you to leave most of your material ordering to us.

But with all that said…if you do prefer to supply material yourself, we want to ensure that you’re set up for success.

3 Best Practices for Supplying Your Own Materials

Here are 3 best practices when supplying your own material for precision machining:

1. Get the material to us on time

As part of our commitment to meeting your important deadlines, we’ll provide you with a date to deliver the material. Receiving materials on time allows us to adhere to our carefully planned production schedules.

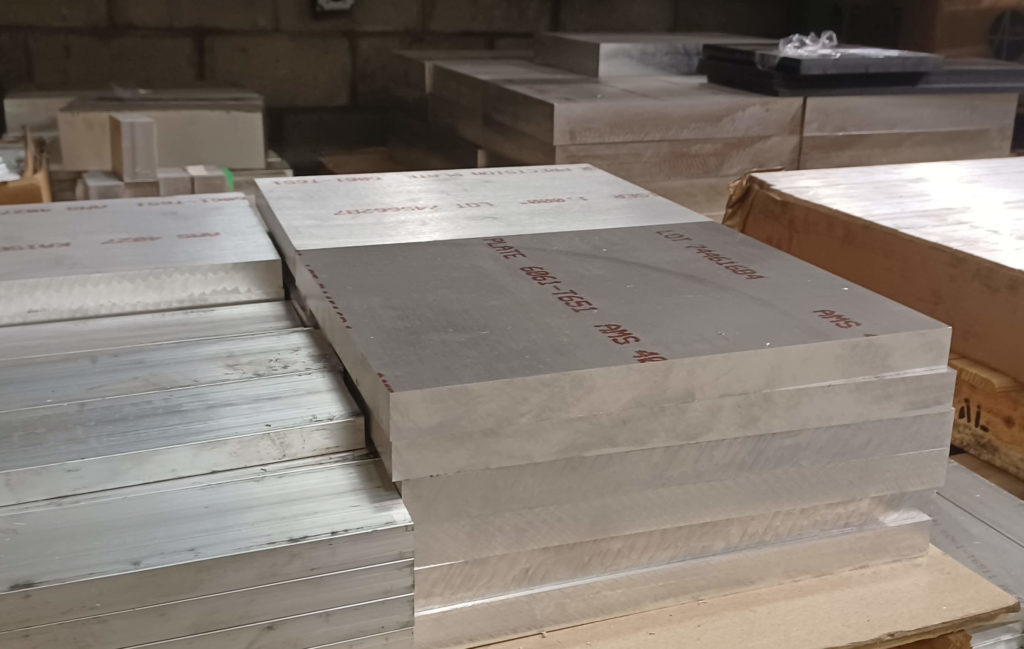

We always account for the time it takes to inspect incoming material. One common issue we encounter is material that’s too thin, so we like to verify that each material meets all critical specifications before precision machining begins.

We’ll have our machines set up and prepped to run your parts on schedule and will need to have the material ready to go to complete your project on time.

2. Buy enough material

Determining how many parts a particular piece of raw material will yield isn’t as straightforward as you might think. You’ll need to provide enough material to account for these factors:

- Test runs. We always test run parts before starting a big production run, which requires a little extra material.

- Part clearance. It’s important to account for clearances around each part on a sheet of material. Even optimally nested parts must have some space between them so we can hold the material in place and meet critical tolerance requirements.

- Risk mitigation. From time to time, unexpected things happen – tool breakage, a power glitch or some other unforeseen event that results in minor fallout. Supplying extra material ensures that we can still complete a full production run even in these instances.

Polyhistor is happy to provide you with the exact dimensions of the material needed for your project, so if you plan to buy material yourself, connect with us first.

3. Allow extra preparation for unusual materials

Getting your parts right is our priority. We have experience working with a wide array of materials, but when we encounter an exotic or proprietary material we haven’t worked with yet, we need a little extra time to master it.

Materials all behave differently during precision machining, so if you supply an unusual material, we’ll need the opportunity to perform a test cut to familiarize ourselves with its properties.

Whether you buy materials yourself or allow us to handle this task as your turnkey contract manufacturing services provider, we’re committed to saving you time, money, and hassle during your project. Request a quote, and let’s make your product succeed!