When developing a part or product for precision machining, it’s important to consider how your design will translate onto the shop floor. Manufacturability issues can increase a project’s cost and lead time, and it’s best to get ahead of any potential roadblocks during the design phase.

Our cost-saving Design for Assembly (DFA) tips have helped customers optimize their assemblies for precision machining, and today we’re pleased to share a few of our Design for Manufacturing (DFM) best practices. (If you want the rest of them, you’ll have to download our free eBook!

DFM Tips: 4 Features to Avoid

Next time you’re designing a part for precision machining, do your best to avoid these features:

1. Thin walls and thin webs

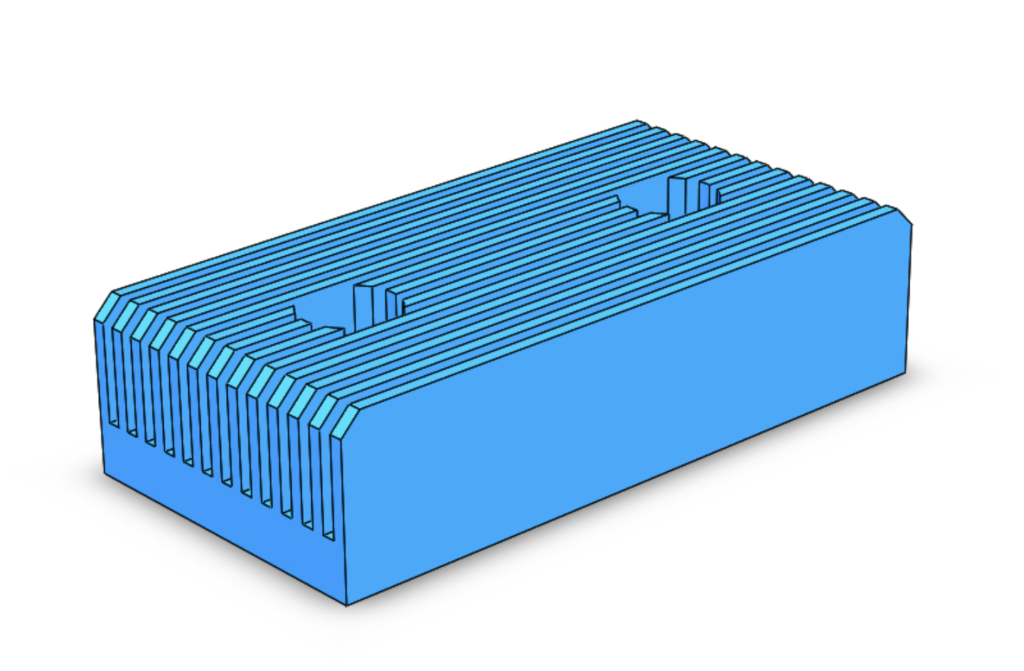

Engineers often design thin walls or thin webs (e.g., a honeycomb pattern) into the internal structure of a part to create rigidity. These features are commonly found in heatsinks.

The problem is that the thinness of the walls or webs also makes them extremely flexible, which causes them to vibrate as they are being cut. The introduction of vibration during precision machining makes tolerance and surface finish issues more likely to occur. Manufacturers must run the machines slowly to prevent these undesirable outcomes, contributing to higher costs and longer lead times.

Determining the right wall or web thickness can be tricky because it depends on factors like part geometry and wall depth. When in doubt, we recommend consulting your precision machining partner for guidance.

2. Undercuts

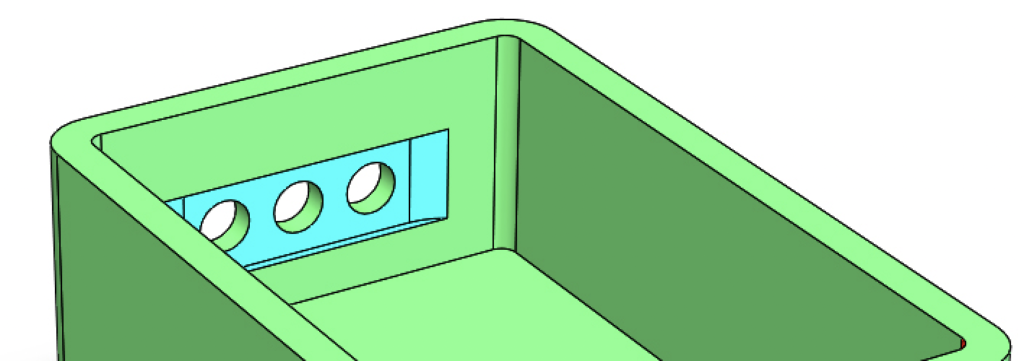

Undercuts are recessed surfaces that are inaccessible with a standard straight tool. They’re commonly used to create snap or latch features that interlock with one another.

When engineers design undercuts into parts, CNC machine shops may need to use special tools like keyway cutters or lollipop cutters to machine these features, which can increase the cost of a project. As with thin walls and thin webs, operators also have to run the machines more slowly to achieve undercuts.

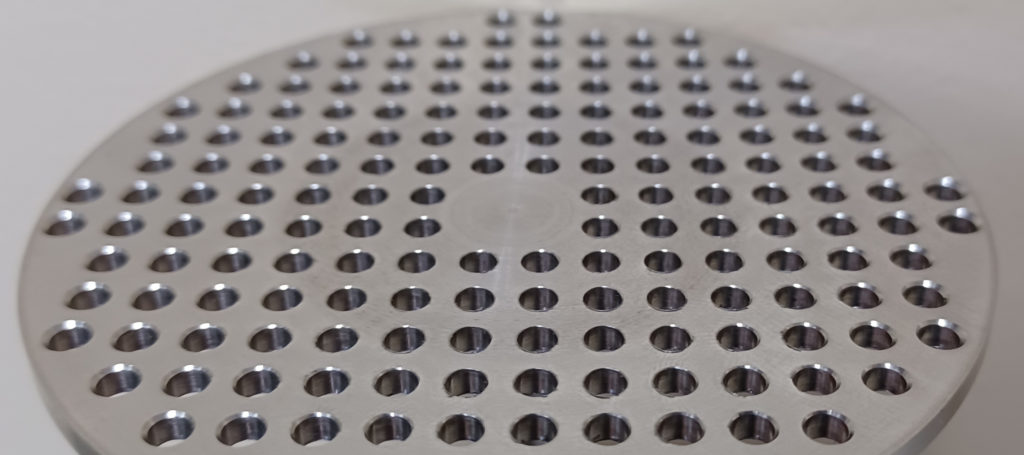

3. Small holes

Generally speaking, the smaller and deeper a hole is, the more challenging it is to cut because longer and thinner tools are more prone to breaking during precision machining. That means—you guessed it—CNC machine shops need to run the machines slower than usual.

The location of a hole and the hardness of the part’s material also factor into the level of machining difficulty. Small holes in the bottom of a pocket or next to a wall can be especially challenging to reach, and hard materials like titanium or Inconel wear tools down quickly.

If you have the opportunity to design larger and shallower holes, doing so can save you time and money.

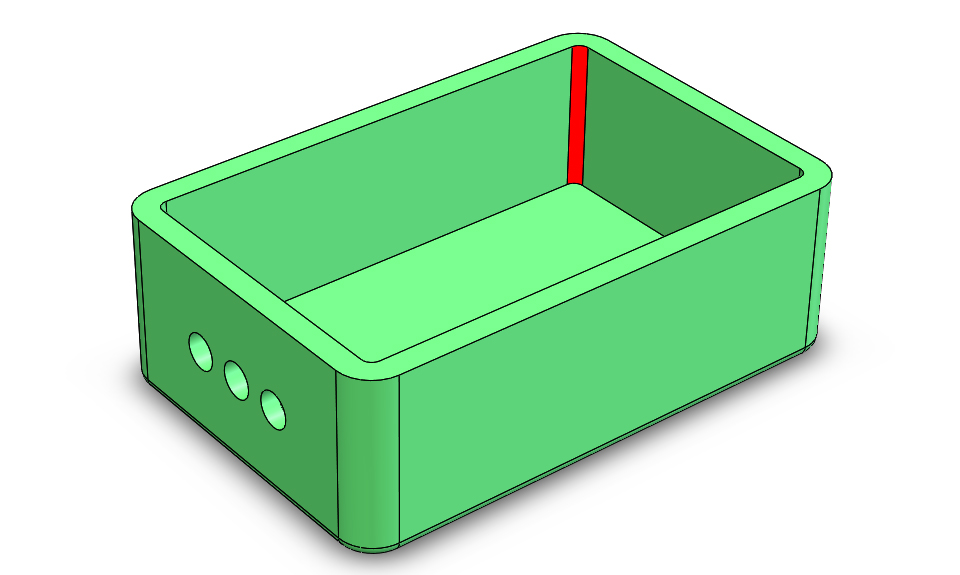

4. Deep pockets with small corner radii

Pockets are an essential consideration when designing parts for precision machining. Like deep holes, deep pockets with small corner radii are difficult for machinists to access and cut. The long and thin custom tools CNC machine shops must use for these features vibrate easily and can compromise the part’s surface finish. These tools can also be harder to source.

When possible, maintain a length to diameter ratio of no more than 5:1 for all pockets so that your manufacturing partner can run the machines quickly and economically using standard tooling.

Keep in mind that these best practices are intended to help you optimize your part designs for precision machining. The right CNC machine shop will work with you to machine any of these features if they’re necessary for your part’s functionality. But if you have some flexibility, avoiding them is one way to ensure reasonable costs and lead times.

No matter what you need, Polyhistor is here to support you. Check out the rest of our DFM tips here, or request a quote to work with us!