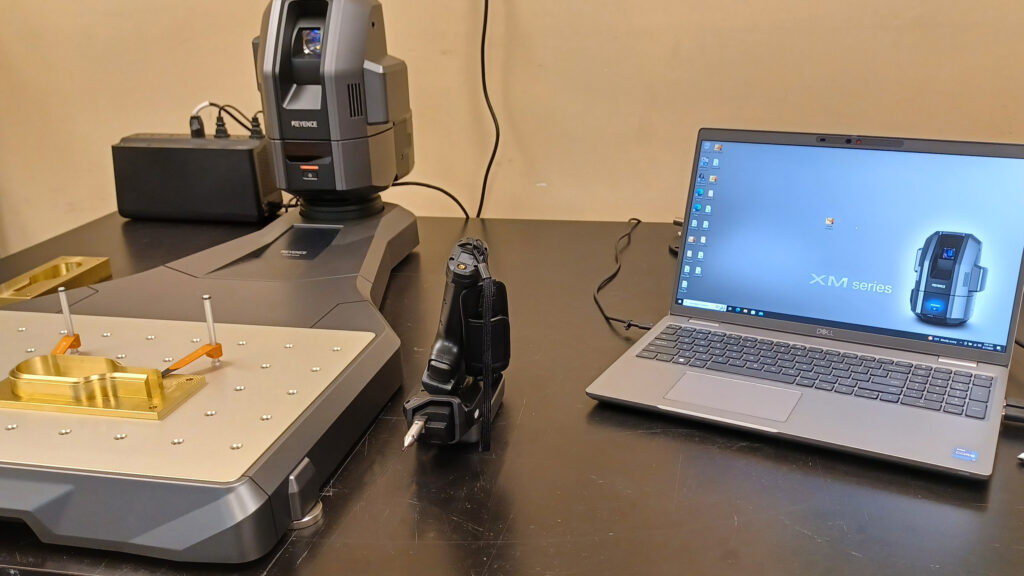

Your low-volume, high-mix precision parts deserve exceptional accuracy. Now, with our precision machine shop’s newly installed Keyence coordinate measuring machine (CMM), we can achieve better accuracy than ever before.

Complex parts with tight tolerances are Polyhistor’s specialty, and the Keyence CMM takes our inspection processes to the next level, ensuring the ultimate accuracy for every specification.

Taking Our Inspection Services to the Next Level

Polyhistor previously performed manual measurements on completed parts, a common practice in many precision machine shops. Calibrated hand tools enable impressive accuracy. But that still wasn’t good enough for us—or our customers.

The sophisticated Keyence CMM supports many beneficial processes and provides vital data that can’t otherwise be obtained.

First Article Inspection reports

With the Keyence CMM, we’re equipped to generate full First Article Inspection (FAI) reports complete with images. The FAI design verification process ensures that your parts meet every specification in your drawings.

Portable measuring

The Keyence CMM device is easy to move from machine to machine and can gather quick measurements without having to remove a part from a machine. Any time a part is removed from the machine, a small amount of accuracy is lost; with the Keyence system, we no longer have to worry about a part becoming out of tolerance during the measuring process.

The Keyence’s portability also allows us to take measurements at any time during CNC machining services. All that’s necessary is a brief pause in machining, and we can verify the part’s dimensions before moving too far along in the process.

Incredible speed

The Keyence CMM is stunningly fast. It’s capable of inspecting an all-new part within 10 minutes. And because the CMM can procure measurements that aren’t apparent to the naked eye or attainable with hand tools, it can detect issues that might otherwise render a part out of spec and in need of reworking, which helps prevent delayed lead times.

Polyhistor Makes Your Tight Tolerance Precision Parts Possible

The Polyhistor team’s impressive blend of engineering, machining, and inspection abilities gives customers a one-stop source for all their tight tolerance precision parts.

From prototype to production, begin your next project with Polyhistor’s precision machine shop by requesting an easy online quote!