Would you like your CNC machined parts engraved or etched with serial numbers, part markings, or even your company logo? Add laser engraving services to your next CNC machining order!

Polyhistor’s Jacksonville, Florida facility provides in-house CO2 laser engraving and fiber laser engraving, giving you access to affordable laser engraving services for everything from individual prototypes to high-volume production runs.

Keep reading to get familiar with laser engraving, its many applications, and the equipment Polyhistor uses to perform this in-demand capability.

Add Laser Engraving Services to Your CNC Machined Parts Order

Laser engraving and etching are feasible on many different metals, plastics, and other materials. Most commonly, we engrave or etch anodized aluminum, brass, and stainless steel.

When performing this add-on service, we first machine the part, then add the required elements with the laser, then complete any required assembly.

Laser engrave your brand name

When a recent customer learned that we offer laser engraving services, they requested that we add laser engraved branding to their CNC turned nozzles. With their name on every nozzle, our customer earns a bit of extra marketing and ensures future orders.

Laser engrave your logo (and add LED lights!)

We’ve laser engraved medical prototypes in the past using a unique approach. First, we 3D printed a clear prototype. Next, we painted the prototype black, then used the laser to remove that paint in the shape of the illuminated text. Colorful LED bulbs backlit the text on the medical device, showing the finished sanitization cycle, showing the finished sanitization cycle.

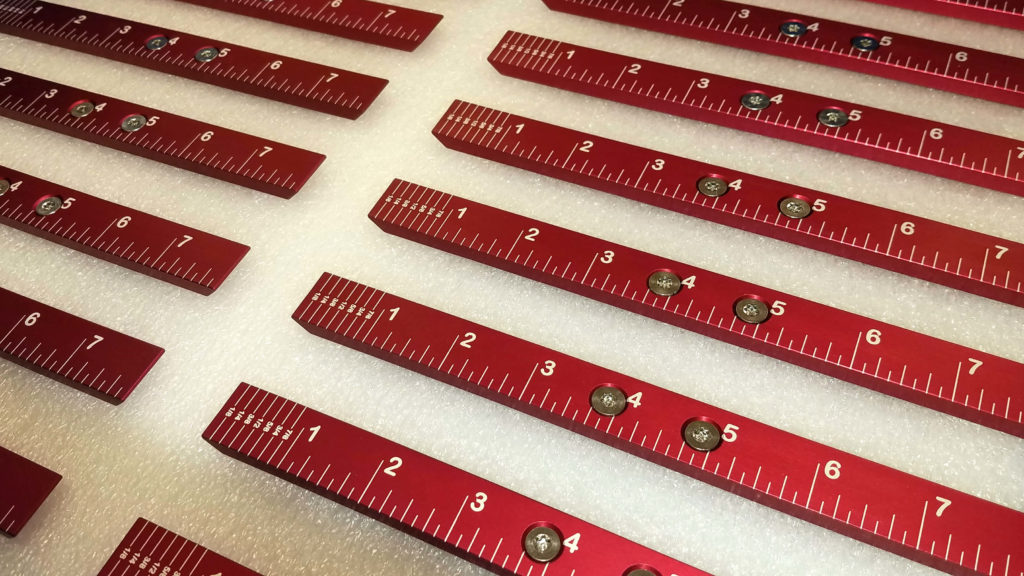

Laser engrave sequential numbers

If you need your parts engraved with unique and sequential serial numbers, we can perform this process in our shop.

FAQ: “Can Polyhistor laser engrave parts made by another shop?”

While it’s certainly possible to laser engrave parts from any shop, we only offer this service for parts we’ve machined in our CNC machine shop.

By combining machining and engraving services, we maintain total quality control over your parts. Should an error occur during the engraving process, we can quickly and easily remake your part, complete the engraving, and deliver your order on time.

Laser Engraving Technologies at Polyhistor

We use two innovative laser engraving technologies: a fiber laser and a CO2 laser. The results appear the same, but the two pieces of equipment work differently and are suited for different types of jobs.

Fiber laser engraving technology

The superior option for fast, accurate laser engraving is the fiber laser. This type of laser cuts up to 5x faster than a CO2 laser, resulting in significantly lower operating costs. Because fiber lasers work so quickly, we perform tens of thousands of fiber laser engravings every year.

The smaller footprint of the fiber laser does create some size limitations, however. In addition, the fiber laser can only engrave non-clear materials. For example, it won’t work for light-colored plastics and clear glass.

Though fiber lasers don’t cut, they do etch. We commonly use our fiber laser to etch and engrave high-accuracy measuring tools and scales, as well as brass parts.

Unlike the fiber laser, our CO2 laser can cut clear materials such as plastic and glass along with etching and engraving. Because CO2 lasers utilize a moving head to position the beam, this technology is slower than fiber laser engraving. However, our CO2 laser equipment can accommodate parts up to 36” x 50”—a significant size increase over the fiber laser.

One of our favorite CO2 laser projects is an etching job for airports. We make large access gates for airport customers by machining clear material and then etching the material’s surface, leaving un-etched sections that form words or graphics. The resulting product is an effective and attractive gate that performs beautifully in the high-traffic airport environment that can also be illuminated.

Get Laser Engraving Services at Polyhistor

To add laser services to your next part order, simply request laser engraving, etching, or cutting when you submit your RFQ. Don’t forget to include your DXF file or vector art—or let us know if you’d like us to create the design file for you. Our accomplished and creative engineers and manufacturing professionals are here to help!