At Polyhistor International, we are proud of our success in partnering with a diverse range of customers. Our ability to assist with product development and our extensive manufacturing capabilities set us apart as a versatile partner to any sector. From medical to lighting, from signage to automotive, we enjoy tackling the challenges that come with […]

Blog

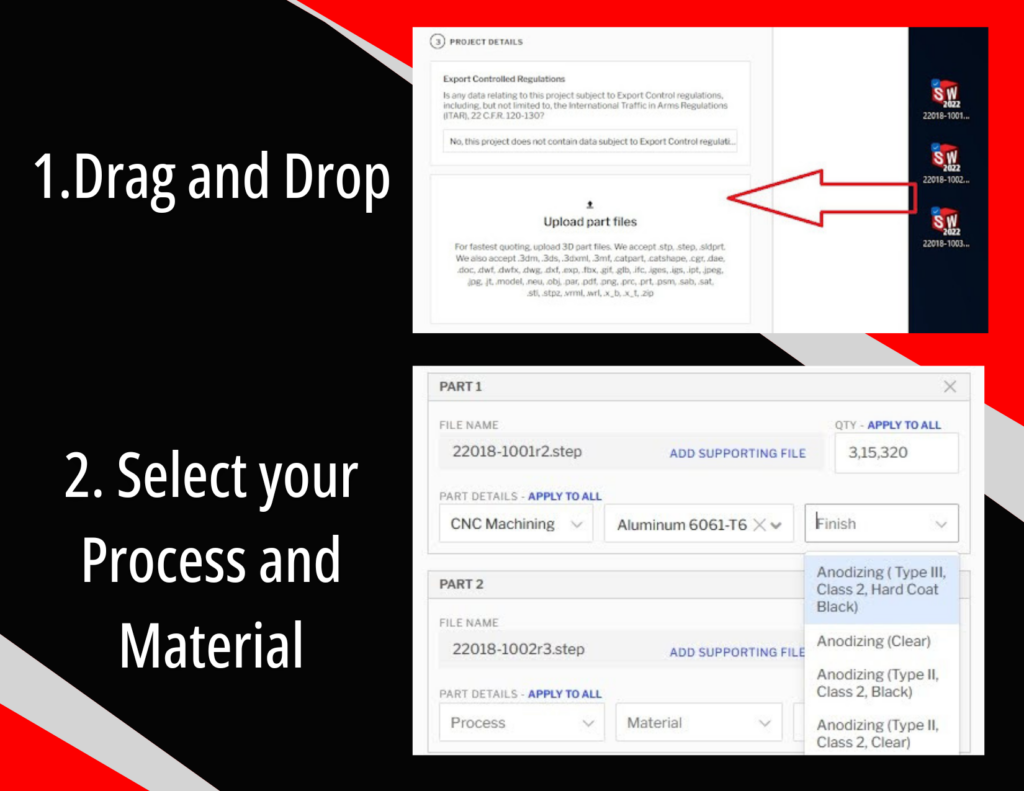

Get Faster, More Accurate Quotes with Polyhistor’s Online Portal

The quoting process may not be the most exciting part of manufacturing, but it’s one of the most critical steps to ensuring project success. At Polyhistor International, we understand how important it is to provide fast, accurate, and transparent quotes to keep your project moving forward. That’s why we’ve developed an online quoting portal designed […]

The True Value of Polyhistor as a Manufacturing Partner

At Polyhistor, we believe we’re a bit different from other manufacturers and CNC machine shops. And that difference shows up even in the terminology we use – we like to think of everyone we do business with as our partner instead of just a “customer.” But is there really a distinction, or are these just […]

The Subtle, Significant Benefits Of Our Reused Packaging

Many of our customers are familiar with Polyhistor’s engineering experience and expertise as a precision machine shop. However, we also like to highlight some of the smaller things they may not realize about Polyhistor. We are excited to showcase our reusable packaging, our waste reduction efforts, and the subtle but significant benefits these initiatives offer […]

Bringing Creativity and Ingenuity to Product Engineering Services

At Polyhistor, we take pride in devising solutions to problems that customers might not even know existed. While other manufacturers prefer a straight and easy path forward, we enjoy navigating the many challenges associated with product engineering services. You’ll never hear the words, “It can’t be done” from us. Instead, we’ll find a better way […]

Laser Cutting: A Versatile Capability with Many Creative Applications

Laser cutting is a versatile manufacturing capability known for its speed and precision. It’s ideal for anything from prototyping to high-volume production. At Polyhistor, we offer in-house laser cutting and laser engraving services from our precision machine shop in Jacksonville, Florida. Versatile Laser Cutting Capabilities When customers need laser cutting services, we rely on two […]

Cost-Reduction Strategies Engineers May Not Consider

There are tremendous opportunities to reduce manufacturing costs for almost every project. The key is to consider and implement cost-saving strategies as early as possible—beginning with engineering design. Keep It Simple: Cost-Saving Product Design Tips Much of the cost to manufacture a product is directly related to how it is designed, assembled, and packaged. Polyhistor’s […]

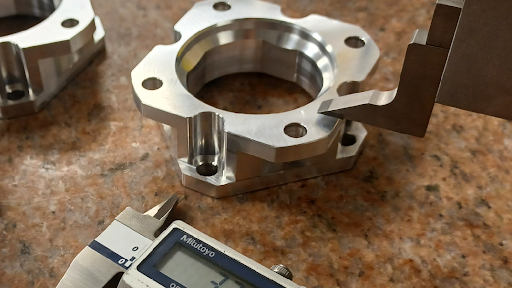

Material Spotlight: Aluminum, a Feature-Rich Material

Aluminum is second only to steel in popularity, and it’s easy to see why! Pure aluminum is plentiful, comprising 8% of the Earth’s crust. In its many alloyed forms, aluminum’s unique properties make it a top choice for a wide range of industries and applications. Let’s explore further. Advantages of Aluminum in Manufacturing At Polyhistor, […]

5 Tips for Selecting the Best Hardware for Any Product

Hardware is critical to any assembly’s success, so we work closely with you to identify the best hardware for your goals. Polyhistor’s unique blend of product design services, on-site engineering expertise, and high-volume CNC machining capabilities equip us to advise you on the various fasteners available and recommend the right solution. Here, we’ve outlined the […]

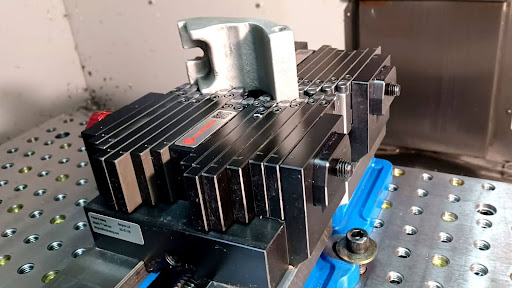

How Modular Vise Systems Promote Manufacturing Efficiency

Even low-volume productions of high-mix parts require workholding, but machining custom jaws for a short production run is almost never efficient or cost-effective. By utilizing modular vise systems in place of custom jaws, our precision machine shop can keep production times short and costs low.