When you offer diverse capabilities like we do at Polyhistor International, partners may not be aware of all the ways we can support their project.

A few years ago, a company initially came to us for product development services. They were thrilled with the results, but turned to another shop for the machining, simply because they didn’t know we could handle both development and machining!

They soon realized their oversight, and they brought production back to our shop. Above all, they needed a scalable manufacturing partner as demand for their product grew, and they realized our adaptability made us the perfect choice.

At Polyhistor, we’re built to grow with your project. Our commitment to your success starts early with design advice, and it can extend all the way through bold investments in new equipment to support your highest production volumes. Discover how we act as your scalable manufacturing partner.

How Far We’ll Go to Scale Alongside You

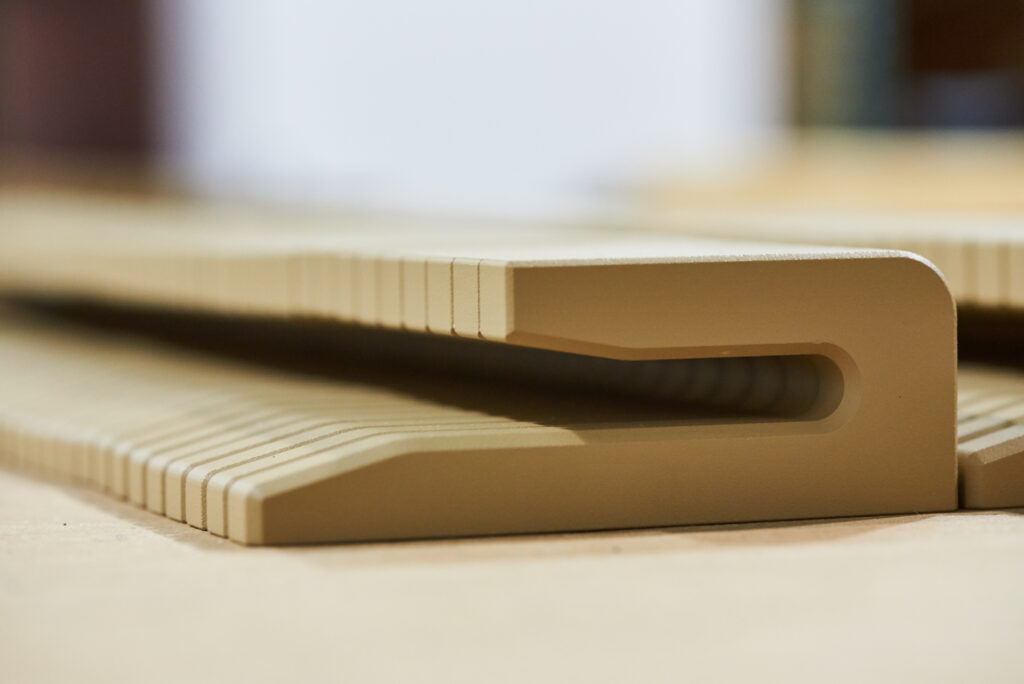

Scalability always starts with smart design. Even the smallest inefficiencies in a prototype can lead to major cost or lead time issues at higher volumes. We prioritize DFM during product development to set the stage for smooth, efficient production later.

Yet design guidance is only the first step. Our shop has structured our investments around scalability. Diverse equipment allows us to machine your part with the most efficient method for your specific material and geometry. Digital tools, like our advanced ERP system, allow us to plan and schedule efficiently as your volumes increase.

Most importantly, we’re willing to make real investments in your success. In many cases, we’ve purchased new machines or even restructured the floor layout to meet a customer’s growing production requirements. Most shops are not interested in bold steps like these due to the potential risks involved. But at Polyhistor, it’s the kind of challenge that excites us.

The Benefits of a Scalable Manufacturing Partner

When you work with one shop at every scale of your project, you’ll see several key benefits that are hard to achieve when you switch partners midstream:

Design continuity: With our product design services, we incorporate scalable manufacturing considerations into your prototype design, so you won’t encounter issues later.

Cost efficiency: Consolidating design and production helps contain costs, such as shipping and administrative overhead, while eliminating redundant quoting and onboarding. And when Polyhistor has aided your design, there will be no unexpected, costly surprises as you enter high-volume CNC machining.

Reduced risk: Relying on multiple vendors increases the chances of miscommunication, misaligned expectations, or inconsistent quality. A single partner minimizes those risks by keeping everything under one roof.

Seamless transitions: As your project moves into high-volume production machining, we already understand your part and your priorities. There’s no learning curve involved, so you can have confidence in both quality and delivery.

What Makes a Good Fit for Scaling With Polyhistor?

Our flexibility and adaptability mean there is no single “ideal” project type for scaling with us. Instead, the primary driver of success is a solid partnership built on communication and trust.

When customers are transparent about their growth plans, timelines, and technical needs, we can proactively plan ahead in all areas, from materials to scheduling to equipment. That kind of alignment allows us to deliver consistent, on-time results even as your needs grow.

Ready to Collaborate With a Scalable Manufacturing Partner?

If you’re looking for a manufacturer that’s as invested in your success as you are, contact Polyhistor today. We’ll help you move from design to any level of scale you need, with the commitment and support of a true partner in your success.

Request a quote today to discuss your project with our Jacksonville machine shop!