Are you considering injection molding for your next project? Injection molding, which consists of injecting molten material into a mold and allowing it to harden, is an excellent solution for high-volume or mass-produced quantities of identical parts. While the upfront cost of tooling for injection molding is more expensive than conventional machining, an initial investment […]

Blog

24 Ways to Reduce Costs for Assemblies

Businesses that rely on manufacturing to make parts and products have faced immense challenges over the last year, from global supply chain shortages to rising costs of raw materials. While it’s encouraging to see America reopening, many of these challenges aren’t going away anytime soon. As businesses ramp up production again, there’s an increasing demand […]

Live Tooling on a Lathe Improves Cost, Lead Time, and Part Quality for Non-Circular Parts

There are many different ways to go about making the same part. But not all shops can, or will, do what it takes to ensure the lowest cost, fastest lead time, and highest quality. If you need a part with a non-circular geometry, the standard assumption has always been that it’s impossible to produce that […]

Avoid These 6 Common Product Design Mistakes

If you’ve ever seen the show “Shark Tank,” you may be inclined to think that developing a new product is as easy as formulating a great idea. All you really need is one great PowerPoint presentation, a killer elevator pitch, some investors and—Boom!—your product will be flying off the shelves, right? We hate to crush […]

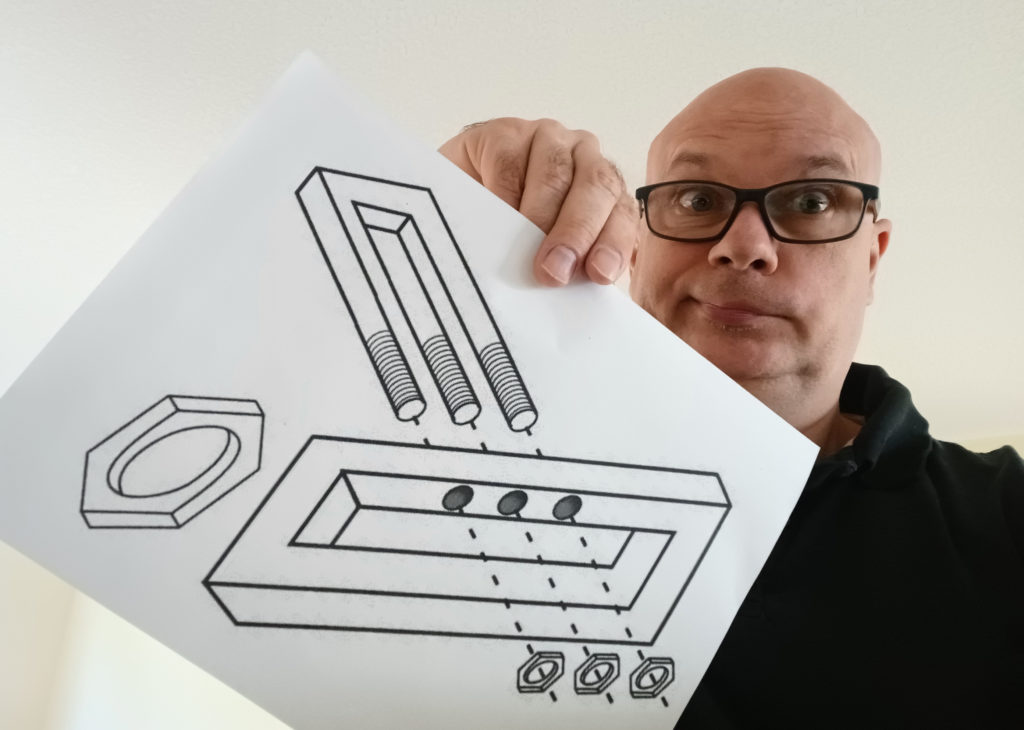

Solving Machining Challenges Through Creative and Innovative Thinking

Manufacturing is almost never a straight and easy path—and that’s one of the reasons it’s so exciting! Each part brings with it a unique set of complexities and requirements that, more often than not, require creative thinking to solve, resolve or address. At Polyhistor, we love a good challenge. As a team of curious engineers, […]

What to Do When You’re Stuck in the Engineering Phase of Product Development

Engineers are known for being meticulous—and it’s easy to understand why: they’re responsible for ensuring that critical parts function properly, so they spend a lot of time perfecting every detail of the product development process. But as the saying goes, “perfect is the enemy of good.” Getting stuck in the engineering phase can be a […]

Ready to develop your next product?

Polyhistor is your one-stop-shop solution Got a big idea for a product? Are you looking for guidance on how to turn your napkin sketch into a functioning prototype? If you’re great at coming up with exciting concepts but need help connecting your ideas to design and manufacturing, the team at Polyhistor International can help. Why […]

Prototyping in Show Quality vs. Standard 3D Printing

Get Your Prototype Ready for Market Testing—Without Tooling! When you’re launching a new product, it’s not always advisable to immediately spend big bucks on mass production. In fact, for the market testing stage, you often only need a couple of prototypes to showcase at a trade show or exhibit. Displaying show quality prototypes allows you […]

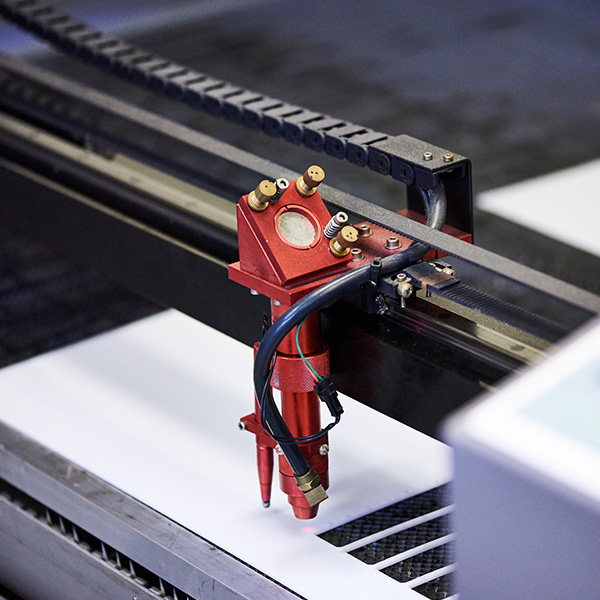

Additive or subtractive manufacturing: what if you didn’t have to choose?

Here’s a manufacturing conundrum: What if you need to produce a part with tight geometric tolerances but have little lead time to spare? How do you build a 3D printed part and achieve tight tolerances at the same time? Some would say you need to machine the part, potentially sacrificing some material or geometric properties […]

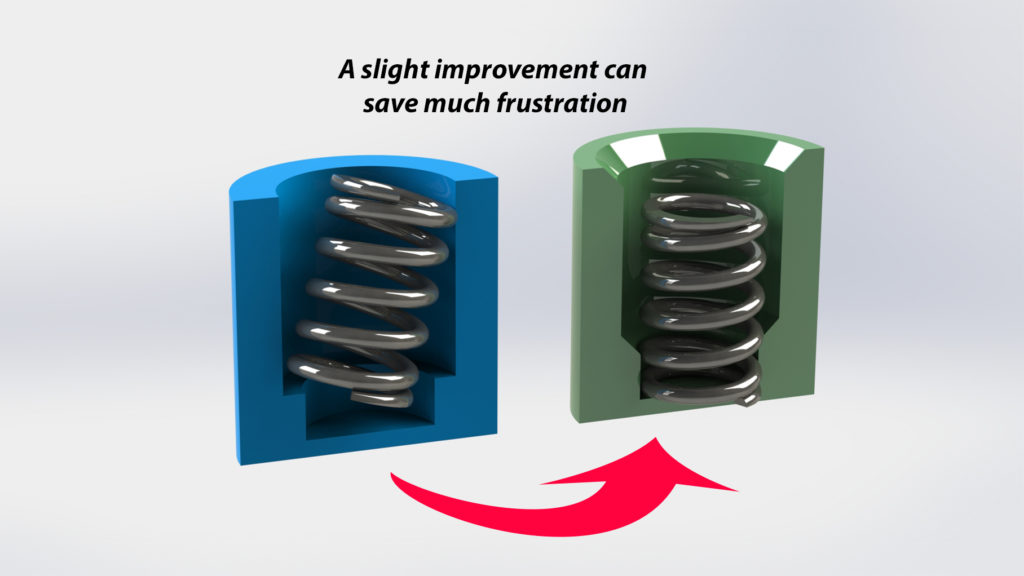

4 Simple Design Tips to Reduce the Cost of Your Part

You’ll save time and money if you begin with the end in mind. The core principle of machining is to remove everything that doesn’t look like the blueprint to get to the part. But the more material you have to remove, the more expensive the part gets—you’re not just wasting material, you’re also racking up […]