There’s a great deal of uncertainty in today’s economic landscape, and it’s directly impacting the manufacturing industry. Material costs are volatile, and lead times can frequently fluctuate. Smart production planning can now be the difference between an efficient, on-time project and costly delays.

How can you ensure your project moves forward smoothly? At Polyhistor International, we often recommend our partners take advantage of blanket orders—long-term purchase agreements that specify deliveries, quantities, and other terms.

Blanket orders drive down your project’s costs, boost reliability and on-time delivery, and can even help in times of unexpected demand spikes. These often simple arrangements can have significant impacts on your success.

Learn why blanket orders have become a key part of many of our most significant partnerships, and find out the characteristics that make a part well suited to this structure.

The Benefits of Blanket Orders With Polyhistor

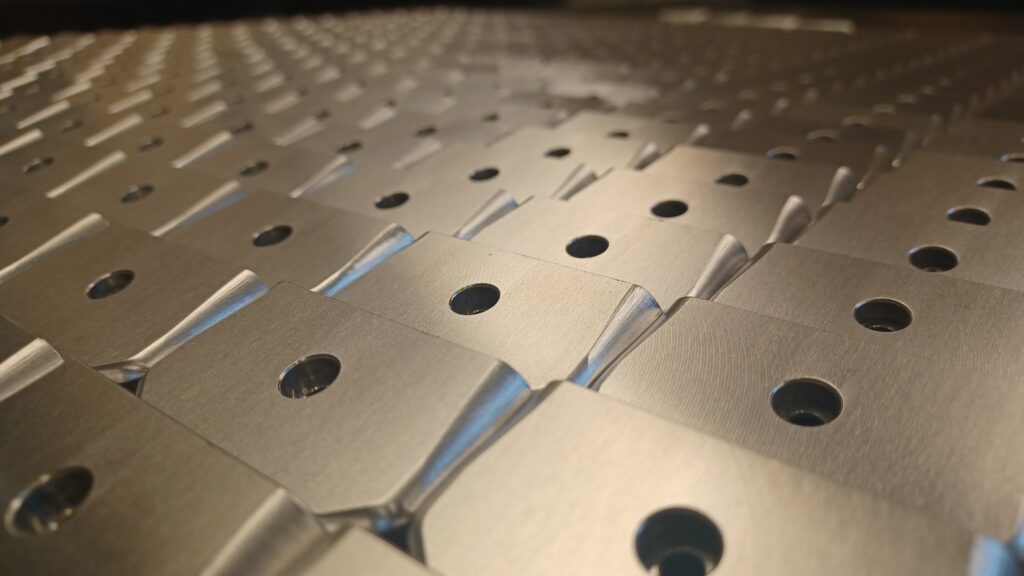

For suppliers and buyers alike, a strict “just-in-time” approach can be appealing, but it often leaves too much up to chance. While we do excel at meeting tight deadlines, we know that long-term planning leads to a deeper partnership. By adopting a blanket order approach with our Jacksonville machine shop, you’ll see benefits like:

Cost Savings and Price Stability

By committing to larger volumes upfront, you unlock the significant savings that come with economies of scale. And those savings are even more critical at times of uncertainty, when locked-in orders shield you from market volatility and potential price swings as policies shift.

Improved Lead Times and Production Efficiency

Long-term visibility allows us to craft the schedule for our CNC machining services around your project’s timeline, rather than trying to fit it in at the last minute. This ensures reliable on-time delivery, and often allows us to get ahead on production. If you face an increase in demand, we may have extra parts already on hand, ready to be quickly delivered.

Simplified Logistics

Instead of submitting frequent purchase orders, customers can issue a single PO with delivery dates outlined throughout the year. That means fewer transactions to process and fewer approvals needed. And on our end, minimized administrative tasks help to eliminate labor, further reducing your costs.

Is a Blanket Order Right for Your Project?

Blanket order strategies can be a good fit for parts of varying quantities, sizes, and complexity. However, there are two key characteristics that make precision machining projects well-suited for blanket orders:

Long-term, predictable demand: Projects should have steady demand that can be clearly outlined in a purchase order.

Mature parts with stable design: Because inventory is manufactured ahead of time, unexpected design revisions can lead to scrap or costly rework, undermining the economic advantages of a blanket order agreement.

Start Planning Ahead With Polyhistor

Are you looking for more predictability in your next project? Partner with Polyhistor to bring greater stability to your supply chain. We offer flexible blanket order structures that can be tailored to any of your high-volume CNC machining needs.

Contact us to discuss a blanket order arrangement for your next project, or request a quote today from our precision machine shop!