The search for a manufacturing partner often begins with metrics like lead time that allow for an easy comparison between suppliers. But after decades in business here at Polyhistor International, we’ve learned that successful partnerships are built on far more than just a single number. Consider the story of one of our repeat customers: they […]

Blog

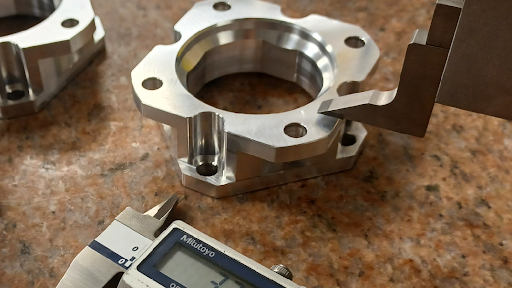

Material Spotlight: Aluminum, a Feature-Rich Material

Aluminum is second only to steel in popularity, and it’s easy to see why! Pure aluminum is plentiful, comprising 8% of the Earth’s crust. In its many alloyed forms, aluminum’s unique properties make it a top choice for a wide range of industries and applications. Let’s explore further. Advantages of Aluminum in Manufacturing At Polyhistor, […]

How 2D Drawings Help Manufacture Better Parts

Fact: 3D CAD technology makes the product design process up to 50% faster than using 2D drawings alone. But does that mean 2D CAD drawings are obsolete? It may surprise you to learn that while 3D CAD models have revolutionized product design, 2D designs still play a very important role in the manufacturing process. Engineers […]

Rapid tooling, rubber grommet

“Yes, but I need parts NOW!!!” A last-minute cable design change required a different grommet to protect a cable as it passed out of an enclosure. Nothing was available off-the-shelf that had the shape characteristics we needed. In this case, we needed the durability, heat resistance, and strength and there were no rapid prototyped material […]

Rapid Prototyped tools for Contract Manufacuting

Our rapid prototyping capability helps us make tools quickly for our contract manufacturing needs. Have you ever been tinkering around and wondered to yourself, “If only I had a tool that could do…” All of the mechanical engineers I know have extensive tool boxes. While it is great to have every driver, wrench and […]

So what do I need to do to have it made?

Rapid prototypes require a 3D CAD file in STL format. If you have one, you can upload the file here. We will send you a quote by e-mail shortly. The rapid prototype can be produced and delivered to you within a few days. But what if my design is not completed? That is where our […]

Going Clear

Lenses and integrated optical housings have traditionally been out of reach of the rapid prototype manufacturing process. In September 2011, Objet released the VeroClear material. We quickly put this innovative new material to work. This was the material we had been looking for to quickly make clear prototypes. We have used this plastic for […]

The Polyhistor Blog

And now for something completely different… 🙂 Our blog posts will focus on rapid prototyping, mechanical engineering, and product development. The rapid prototyping field is changing every day. It changes the way products are designed, tested, and eventually produced. In time, this technology is poised to change the face of manufacturing as this process gets […]