At Polyhistor International, we do everything we can to keep the quoting process fast and straightforward, whether you use our online portal or reach out another way. No matter how you submit your machining RFQ, we always ask for both a 2D drawing and a 3D model, along with the other key project details we need to quote accurately.

Even so, we often receive only one file or the other. That’s a helpful start, but there are reasons we truly need both files. Each file serves a different purpose and typically includes critical information that the other doesn’t have.

The Role of 3D Models and 2D Drawings

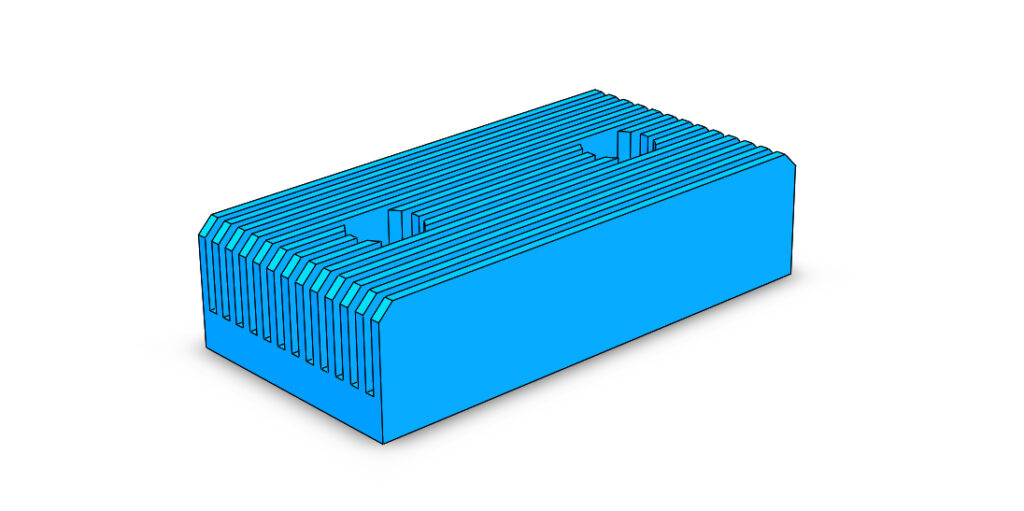

A STEP file gives us the clearest view of your part’s 3D geometry. It helps us evaluate features, part complexity, and potential manufacturing issues. The file is also used directly in both our quoting and programming technology.

A 2D drawing is usually where requirements are defined. Drawings commonly capture what a model does not, including tolerances, surface finish callouts, inspection, or special process requirements, and more.

These files are essential for successful precision machining, and they’re just as important to product development services. A strong 3D model helps define the design, but a clear 2D drawing ensures your requirements are understood, and the design becomes a manufacturable part.

Why Both Files Together Lead to Better Outcomes

When we have both a STEP file and a 2D drawing, there are a few practical benefits:

- Quicker, more accurate quotes: We can pull geometry from the STEP file while validating requirements in your drawing, making it easier to provide accurate pricing and lead times.

- Better Design For Manufacturing (DFM) guidance for lower costs: After you submit your machining RFQ, our quoting technology uses your 3D model to identify features that may be expensive to machine. When we flag those opportunities early, we can recommend adjustments that lower cost without affecting your design’s functionality.

- Efficient programming and faster production: Modern programming relies on 3D models. If you can only provide us with a drawing, we may need to create a model for our programming. That adds to your timeline, and it also increases the chance of errors when the 3D model and 2D drawing weren’t created or maintained by the same designer.

Catching File Mismatches to Prevent Errors

Another valuable reason to submit both files is that, as we examine the files, we are effectively able to cross-check them against each other. It’s not uncommon to find discrepancies, maybe because an updated drawing was paired with an older model (or vice versa).

When we find an issue, we contact you to determine your intent before moving forward. Our shop has a documented feedback loop so that clarifications or revisions are approved before production proceeds.

That may add a short delay up front, so if your project is time-sensitive, it always helps to be sure you’re submitting matching up-to-date files in your machining RFQ. Either way, catching the issue early is far better than discovering it after parts are already machined, when it can result in costly scrap or rework.

Let’s Hit the Ground Running!

We want your next project to proceed smoothly from the start. When you include both the STEP file and the 2D drawing in your RFQ, you’re helping ensure we can be as efficient as possible in your manufacturing. Whether you need high-volume production machining or product design services, both files are critical to your success.

Have any questions about your model, or just need to discuss the quoting process with us? Contact us today!