When you offer diverse capabilities like we do at Polyhistor International, partners may not be aware of all the ways we can support their project. A few years ago, a company initially came to us for product development services. They were thrilled with the results, but turned to another shop for the machining, simply because […]

Blog

Custom Tooling: A Behind-the-Scenes Strategy That Drives Your Project’s Efficiency

At Polyhistor International, we’re always looking for every possible way to make your project more efficient and cost-effective. It’s part of our collaborative mindset—we view all of our customers as true partners. We’re committed to enabling their success in any way we can, whether through custom order options or design for manufacturing guidance. One behind-the-scenes […]

Accelerating High-Volume Machining With Our Equipment and Expertise

As a trusted name in American-made, high-volume machining, Polyhistor International is known for pushing the limits of throughput — without ever sacrificing quality. We’ve earned a reputation for precision and performance among our partners, and we don’t believe in settling for “good enough.” We’ve Invested in What Matters — So You Don’t Have To. By […]

Engineer Defense Enclosures to Withstand Extreme Conditions

At Polyhistor International, our decades as a defense supplier have taught us the challenging conditions mission-critical equipment will face. Products must perform equally well in the scorching desert and frigid Alaskan conditions alike, all while maintaining sealing and protection. When we manufacture defense-grade enclosures in our CNC machine shop, we’re creating shields to protect critical […]

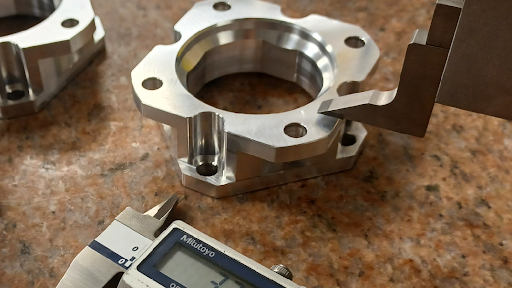

Optimizing High-Volume Production: Strategies for Cost-Efficient Scale-Up

The transition from prototyping to large scale production can be a complex and expensive process for many companies. Without proper planning, decisions that were adequate for the production of a handful of parts will become extremely inefficient for producing thousands. At Polyhistor International, we’re experts in both prototyping and high-volume CNC machining. While many view […]

5 Essential Qualities in a Great Manufacturing Partner

The search for a manufacturing partner often begins with metrics like lead time that allow for an easy comparison between suppliers. But after decades in business here at Polyhistor International, we’ve learned that successful partnerships are built on far more than just a single number. Consider the story of one of our repeat customers: they […]

Tackling Tight Deadlines: How Polyhistor Delivered Critical Parts Over a Holiday Weekend

A few years ago, as Independence Day approached, our plans mirrored those of millions of other Americans: We expected a relaxing long weekend full of fireworks and grilling. Suddenly, a defense contractor contacted us with an urgent request: they needed parts within five days—including the holiday weekend. The contractor was a long-time partner, and we […]

Material Spotlight: Aluminum, a Feature-Rich Material

Aluminum is second only to steel in popularity, and it’s easy to see why! Pure aluminum is plentiful, comprising 8% of the Earth’s crust. In its many alloyed forms, aluminum’s unique properties make it a top choice for a wide range of industries and applications. Let’s explore further. Advantages of Aluminum in Manufacturing At Polyhistor, […]

5 Tips for Selecting the Best Hardware for Any Product

Hardware is critical to any assembly’s success, so we work closely with you to identify the best hardware for your goals. Polyhistor’s unique blend of product design services, on-site engineering expertise, and high-volume CNC machining capabilities equip us to advise you on the various fasteners available and recommend the right solution. Here, we’ve outlined the […]

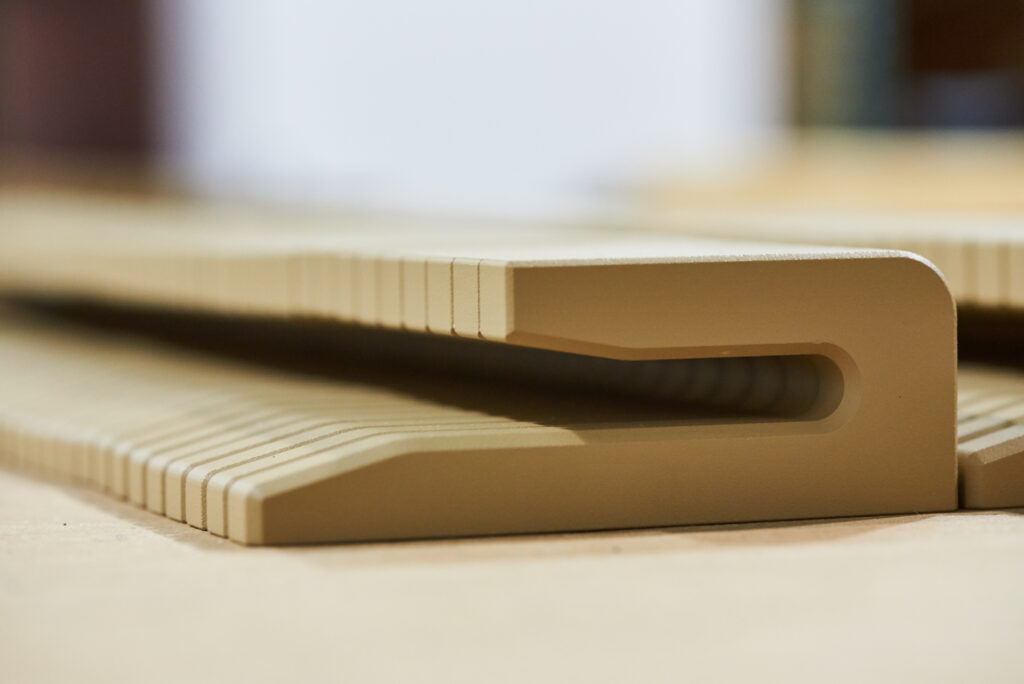

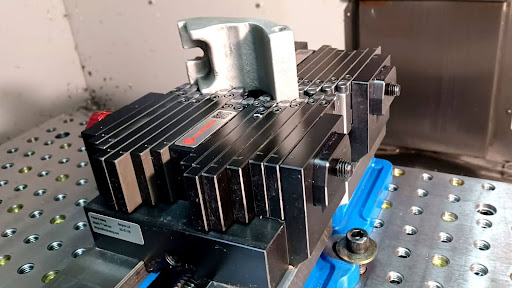

How Modular Vise Systems Promote Manufacturing Efficiency

Even low-volume productions of high-mix parts require workholding, but machining custom jaws for a short production run is almost never efficient or cost-effective. By utilizing modular vise systems in place of custom jaws, our precision machine shop can keep production times short and costs low.