Connecting the dots between design and manufacturing is a core capability for us at Polyhistor International. When you leverage our design for manufacturing services, we not only offer suggestions on what could drive up cost and lead time, but we also clearly explain the reasoning in the language of engineers. That’s because our owner and […]

Blog

Why Your Machining RFQ Needs Both a 3D Model and a 2D Drawing

At Polyhistor International, we do everything we can to keep the quoting process fast and straightforward, whether you use our online portal or reach out another way. No matter how you submit your machining RFQ, we always ask for both a 2D drawing and a 3D model, along with the other key project details we […]

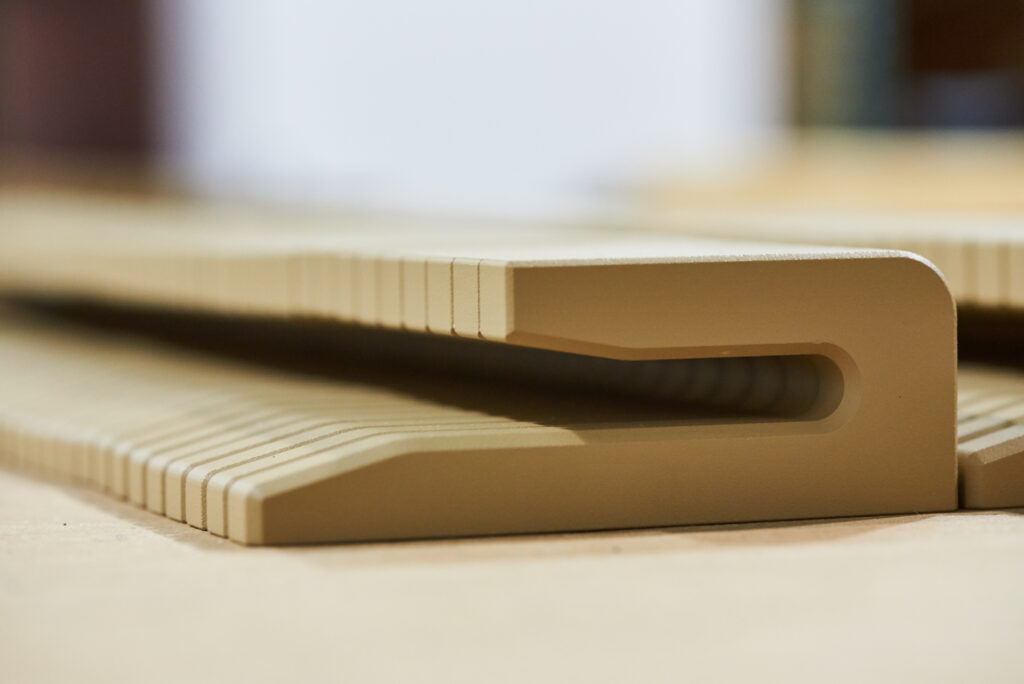

In-House Engineering and Design Services For Your Defense Manufacturing

At Polyhistor International, we’ve supported the defense sector for more than 20 years, giving us a deep understanding of what our partners in this space need most. Because proper design can be so critical to a project’s timeline, many of our defense manufacturing clients especially value our in-house design capabilities. These services combine prototyping expertise, […]

3 Lessons from a Product Development Company: Avoiding Delays and Rework

As a product development company, Polyhistor International has spent many years guiding partners through every stage of the development process. While we never stop learning new lessons, the most valuable principles are applicable to every project we take on. When these fundamentals aren’t in place, projects can easily run over schedule or exceed their budget. […]

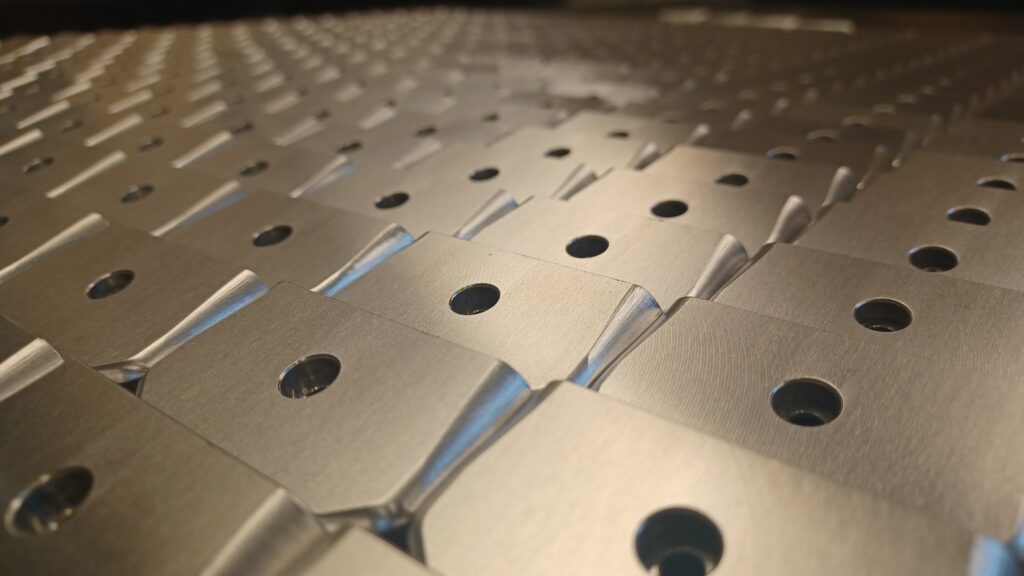

How to Choose a Manufacturer for High Volumes: 4 Early Questions to Ask

At Polyhistor International, we love talking to prospective customers about our high-volume CNC machining services as they choose a manufacturer for their project. It’s a chance to learn more about unique products and specific challenges facing different industries, and we relish every opportunity to learn. Of course, we always let these potential partners know they […]

Product Development Services: Tackling the Unfamiliar and Applying the Lessons

When our owner, Peter Schönning, started Polyhistor International, he expected to spend his days solving engineering and precision machining problems. He was ready to offer design-for-manufacturing guidance, strategize the best machining methods, and apply his background in mechanical engineering to new challenges. What he did not expect was that his role would one day have […]

The Benefits of Reshoring With an American Manufacturing Partner

Manufacturing has faced a great deal of regulatory and legislative uncertainty this year, and many businesses are reevaluating their supply chains as a result. At Polyhistor International, we’re having more conversations with customers who are considering reshoring their precision machining with a U.S.-based partner. But reshoring isn’t just a reaction to recent events. For decades, […]

A Scalable Manufacturing Partner Ready to Invest in Your Success

When you offer diverse capabilities like we do at Polyhistor International, partners may not be aware of all the ways we can support their project. A few years ago, a company initially came to us for product development services. They were thrilled with the results, but turned to another shop for the machining, simply because […]

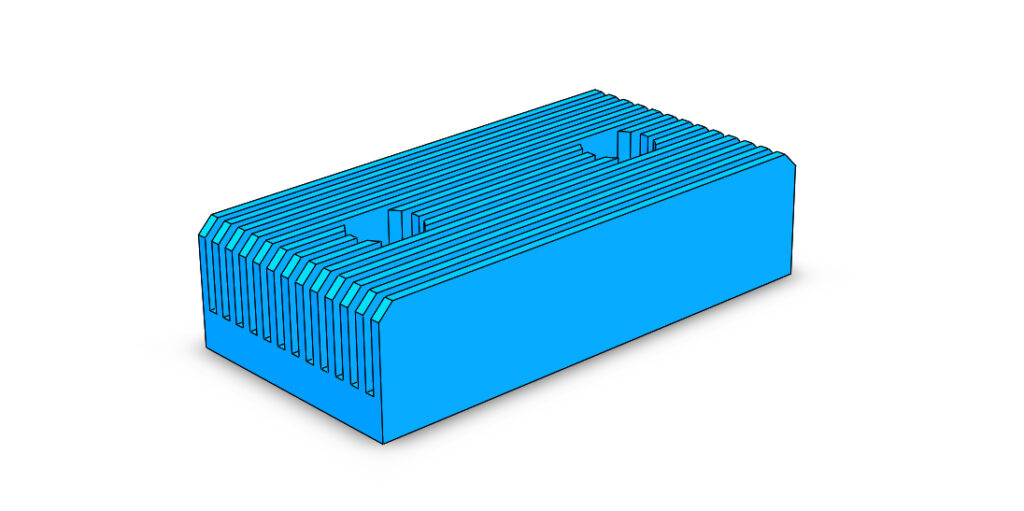

Custom Tooling: A Behind-the-Scenes Strategy That Drives Your Project’s Efficiency

At Polyhistor International, we’re always looking for every possible way to make your project more efficient and cost-effective. It’s part of our collaborative mindset—we view all of our customers as true partners. We’re committed to enabling their success in any way we can, whether through custom order options or design for manufacturing guidance. One behind-the-scenes […]

Blanket Orders: Save on Costs and Manage Uncertainty in Your Manufacturing Project

There’s a great deal of uncertainty in today’s economic landscape, and it’s directly impacting the manufacturing industry. Material costs are volatile, and lead times can frequently fluctuate. Smart production planning can now be the difference between an efficient, on-time project and costly delays. How can you ensure your project moves forward smoothly? At Polyhistor International, […]